VALCO Valley Tool & Die, Inc.

VALCO Valley Tool & Die, Inc.Request A Quote

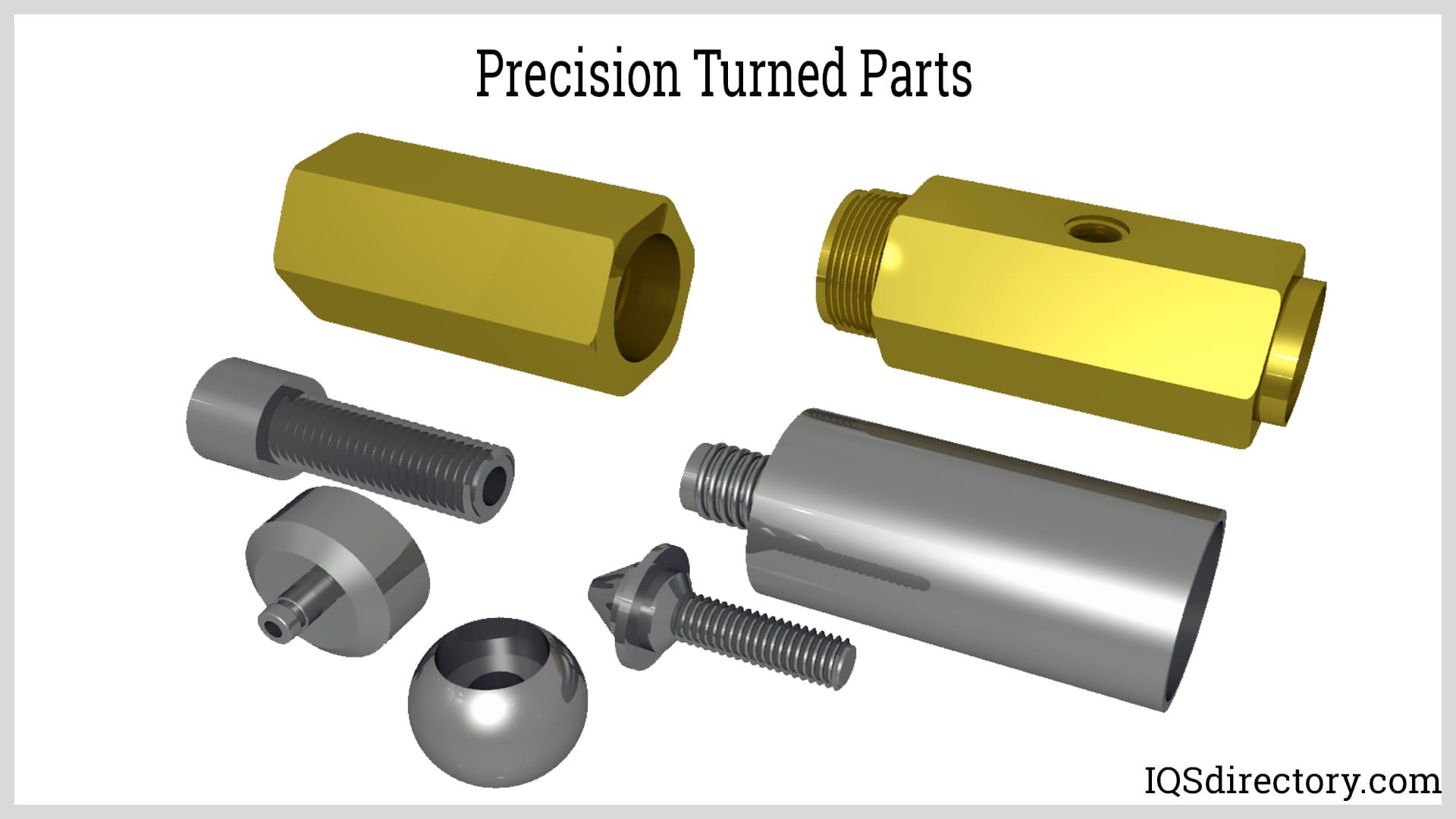

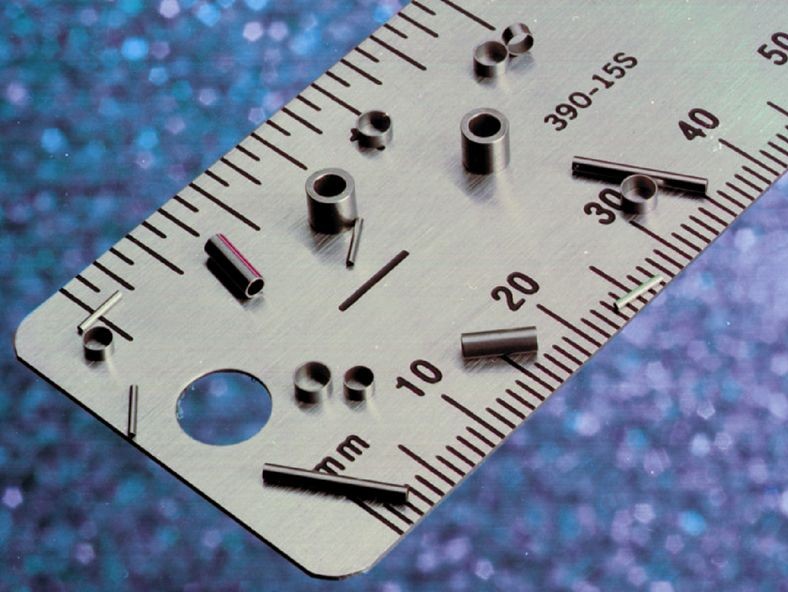

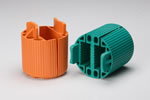

North Royalton, OHVALCO Valley Tool & Die, Inc. is a leading manufacturing company specializing in the production of high-quality Screw Machine Products. With a rich heritage of over 50 years in the industry, VALCO has established itself as a trusted and reliable provider of precision-engineered components for a wide range of applications. At VALCO, we are dedicated to delivering exceptional products and services that meet the unique needs of our customers. Our state-of-the-art facility, located in the heart of the industrial hub, is equipped with advanced machinery and cutting-edge technology, enabling us to produce complex screw machine products with unmatched precision and efficiency. Our Screw Machine Products are manufactured using a variety of materials, including stainless steel, brass, aluminum, and various alloys. We have extensive experience in working with these materials, allowing us to meet the most demanding requirements and deliver products that meet the highest industry standards. One of the key strengths of VALCO is our team of highly skilled engineers, machinists, and technicians. With their expertise and attention to detail, we ensure that every component we produce adheres to strict quality control measures. Our commitment to quality is further reinforced by our ISO 9001:2015 certification, which underscores our dedication to continuous improvement and customer satisfaction. We offer a comprehensive range of Screw Machine Products, including but not limited to: 1. Screws and Fasteners: VALCO specializes in the production of precision screws and fasteners, customized to meet specific dimensional and functional requirements. Our screws and fasteners are utilized in various industries, such as automotive, aerospace, electronics, and consumer goods. 2. Connectors and Fittings: We manufacture a diverse range of connectors and fittings, designed to ensure secure and reliable connections in industrial applications. Our connectors and fittings are known for their durability, precision, and compatibility with different systems. 3. Bushings and Spacers: VALCO produces high-quality bushings and spacers used for precise alignment and spacing in mechanical assemblies. Our products are engineered to provide excellent load-bearing capabilities and resistance to wear and tear. 4. Pins and Shafts: Our precision-engineered pins and shafts are essential components in various machinery and equipment. They are designed to transmit rotational motion or act as guides within mechanical systems, ensuring smooth operation and optimal performance. In addition to our exceptional product offerings, VALCO is committed to providing superior customer service. We work closely with our clients to understand their specific requirements, offering personalized solutions and technical expertise. Our team is responsive, reliable, and dedicated to meeting project timelines and exceeding customer expectations. In summary, VALCO Valley Tool & Die, Inc. is a trusted manufacturer of Screw Machine Products, delivering precision, quality, and reliability to industries worldwide. With our advanced capabilities, experienced team, and customer-centric approach, we are well-equipped to meet the evolving needs of our clients and provide them with the highest level of satisfaction.

Broaching

Broaching CNC Machining

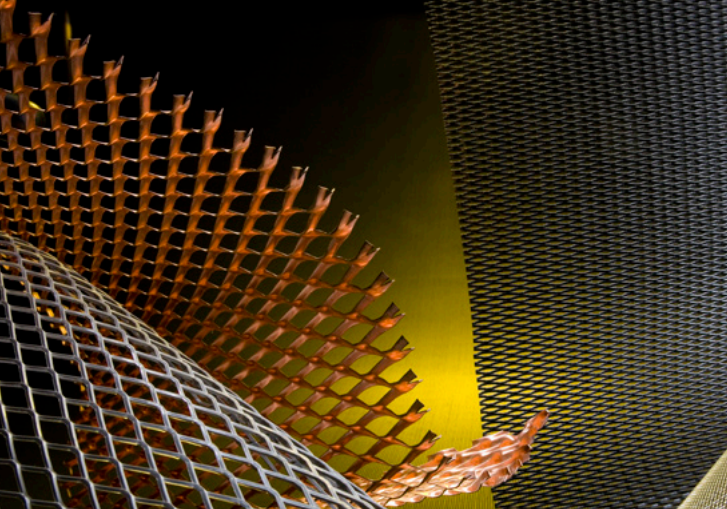

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

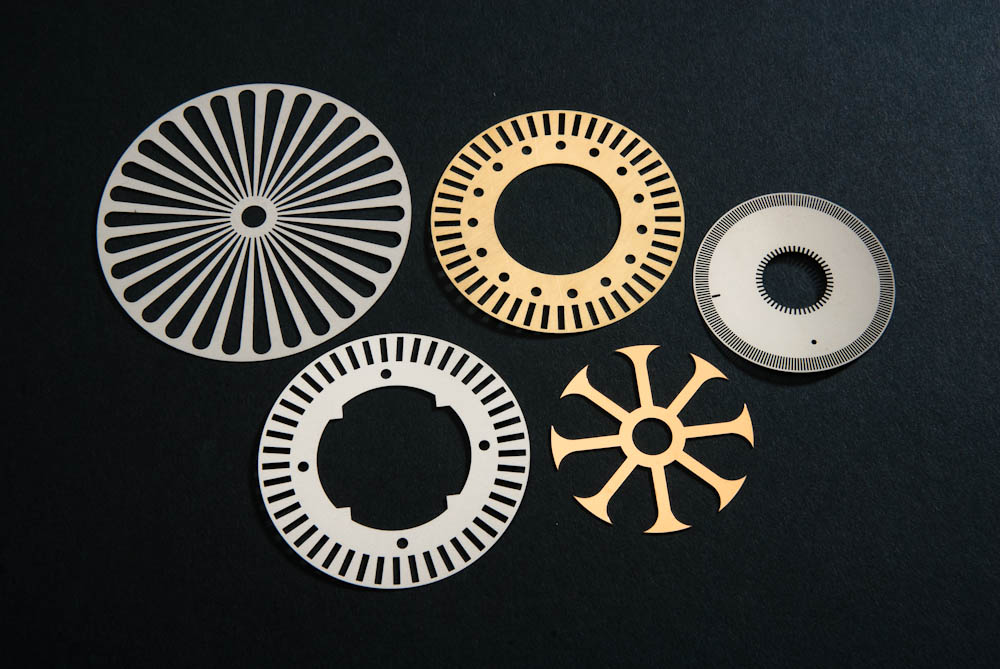

Laser Cutting Metal Etching

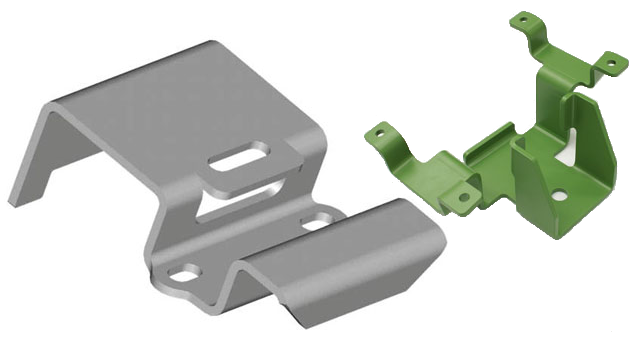

Metal Etching Metal Fabrication

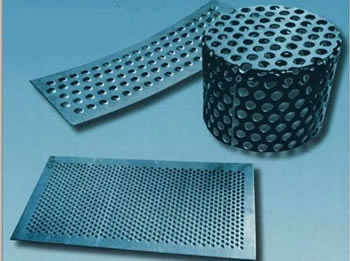

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services