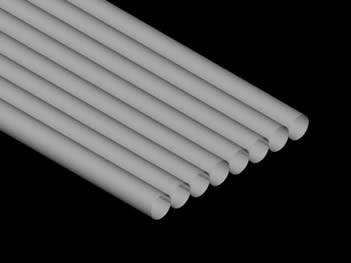

Best suited for softer metals such as aluminum and standard grade steel, frequently knurled objects include tool handles, metal flashlights, knurled nuts, knurled control knobs, barbell bars, metal shafts, knurled winged screws, mechanical pencils and metal tubes. Knurling is particularly useful when it comes to assembling a high precision part into a hole in a low precision part when the hole does not closely match the diameter of the high precision part. Read More…

H & R Screw Machine Products-ISO 9001-certified manufacturer of high-volume screw machine products for many industries. We also produce CNC turned parts and provide machining of customer supplied castings, forgings and stampings.

It is Thuro’s mission to be the leading choice for screw machine parts, and to offer our products at the highest quality and the lowest cost. Our team members dedicate themselves to ensuring that our customers receive the perfect part on time, every time.

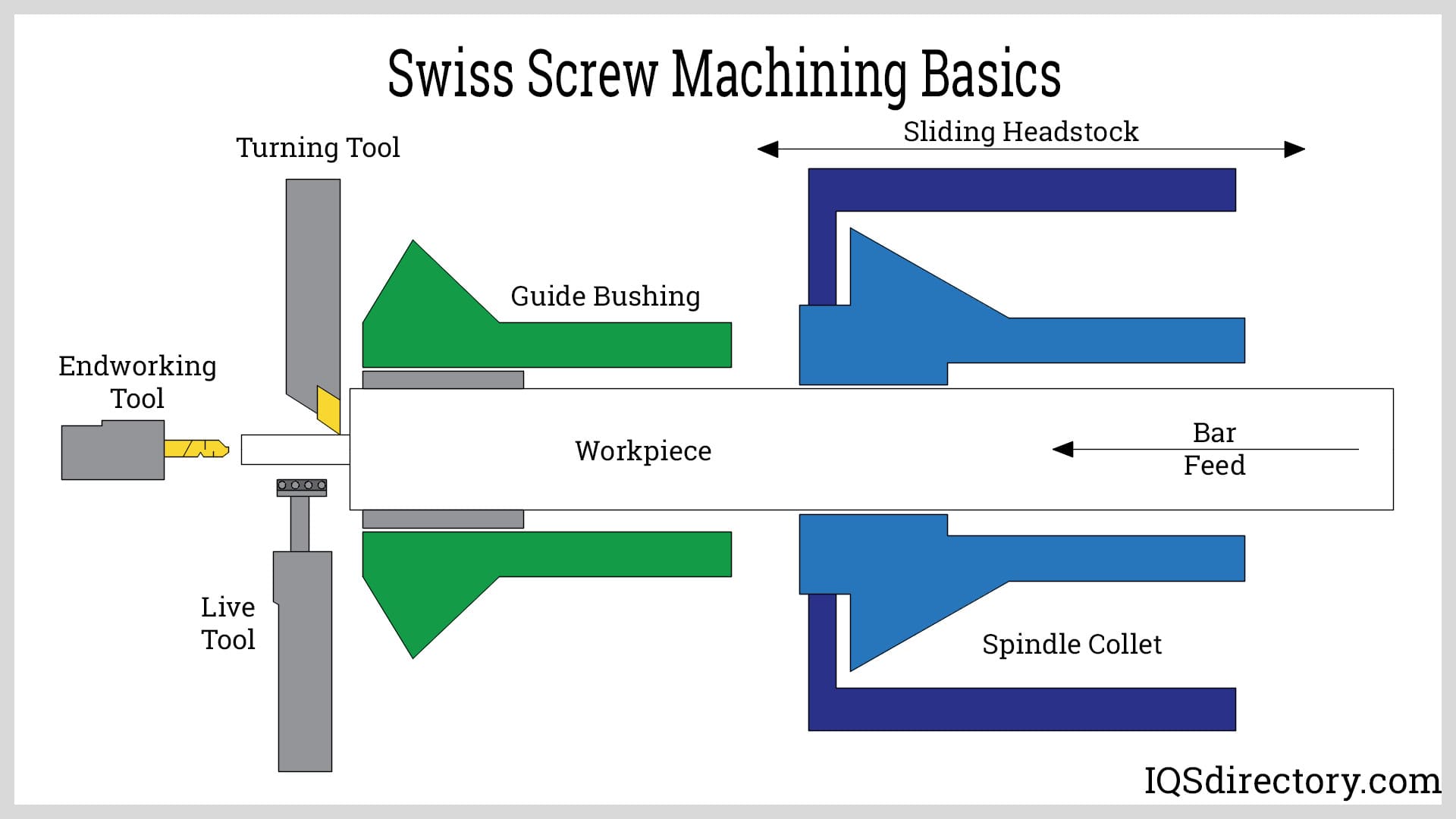

Based out of California, Pacific West America, Inc. (PWA) is a metal fabrication company. We focus most of our efforts on swiss screw machining, stampings, and precision parts, and our electronics division makes products such as cable assemblies, connectors, circuit boards and membrane switches. We create our products using a variety of CNC controlled machines, processes and robotics. Such...

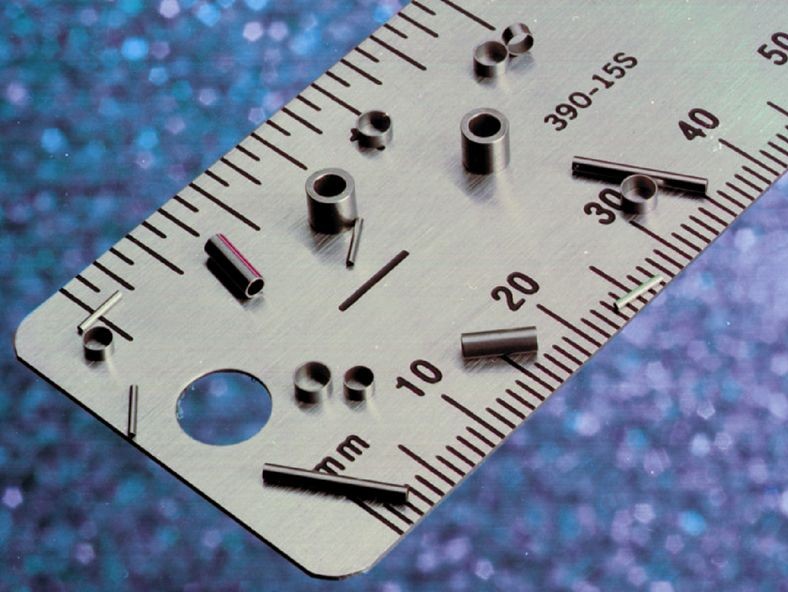

At M.A.R.'s Engineering, we take great pride in our ability to deliver high-quality screw machine products. Our screw machines are capable of producing complex components with utmost precision and efficiency. Whether it's small parts or intricate assemblies, we have the expertise and equipment to meet your specific requirements. With a wide range of materials and finishes available, we can...

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Dynamic Machining X Manufacturing, LLC is a leading provider of precision machining services, specializing in medical machining, aerospace parts manufacturing, mill-turn center operations, 5-axis machining, and more. Our state-of-the-art facilities and highly skilled team enable us to deliver complex and intricate components with unparalleled accuracy and quality. Serving a wide range of...

At Lakeside Screw Products, we pride ourselves on delivering exceptional screw machine products crafted with precision and quality. Our commitment to excellence is ingrained in our rigorous quality control process, ensuring that every component we produce meets the highest standards of accuracy and reliability. Since 1977, Lakeside Screw Products has been a trusted partner, providing unparalleled ...

More Knurling Manufacturers

The knurled pattern on the high precision part presses into the knurled walls of the low precision part and forges a connection that otherwise would not have been. In addition, knurling offers extensive manufacturing and repair applications that allow knurling companies to serve diverse industries such as electronics, automotive, construction, aerospace, telecommunications, fitness equipment and marine.

Most often conducted on a lathe, knurling is commonly achieved through the same automatic-feed mechanisms that are used to form screw machine products. Knurling tools are used in conjunction with the lathe and enable the embossing of the pattern. Embossing is the process of creating a three-dimensional design on a part or material.

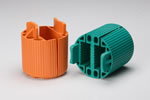

There are four general knurling patterns: annular rings, straight, angular and diamond knurl. These knurling patterns can be used independently or in a combination. Annular rings are most often used when using a plastic mating component. While annular rings allow for easy mating, the ridges can make the components difficult to pull apart. A straight knurling pattern is also referred to as a linear knurl pattern and consists of a series of linear straight ridges. The straight ridges can also be formed into helical grooves referred to as a helical knurling pattern.

Angular knurling consists of straight ridges in an angular direction and is typically used in order to give extra traction to an external handle or other connective piece. The most common type of knurling pattern for hand grips is diamond knurl because it creates the most traction between a user's hand and the handle. A diamond knurl consists of a criss-cross pattern of ridges.

Broaching

Broaching CNC Machining

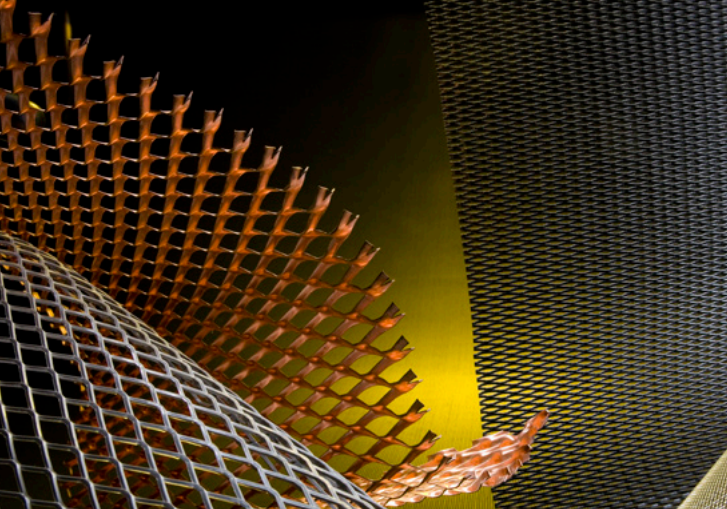

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

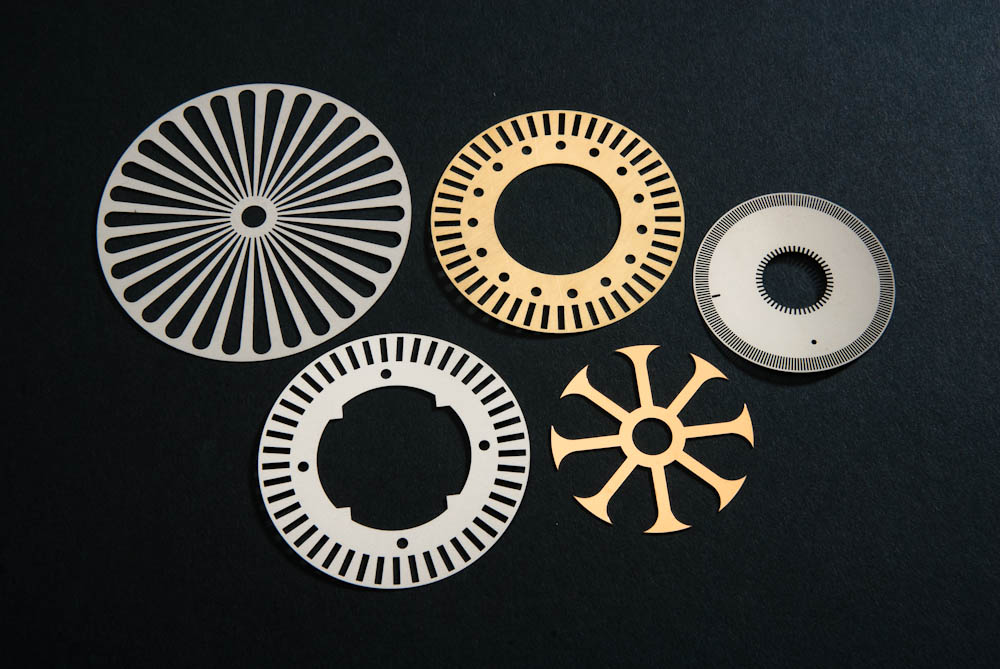

Laser Cutting Metal Etching

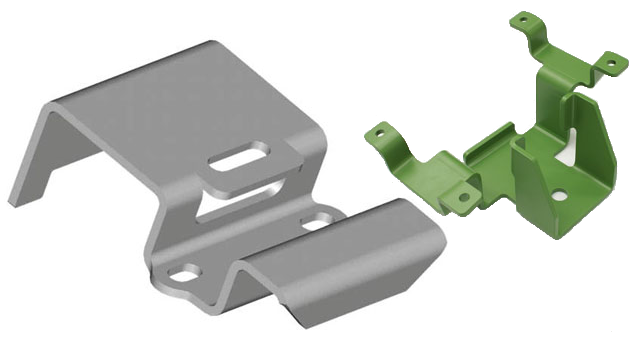

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

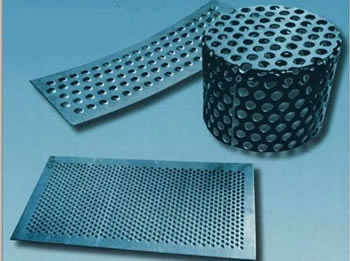

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services