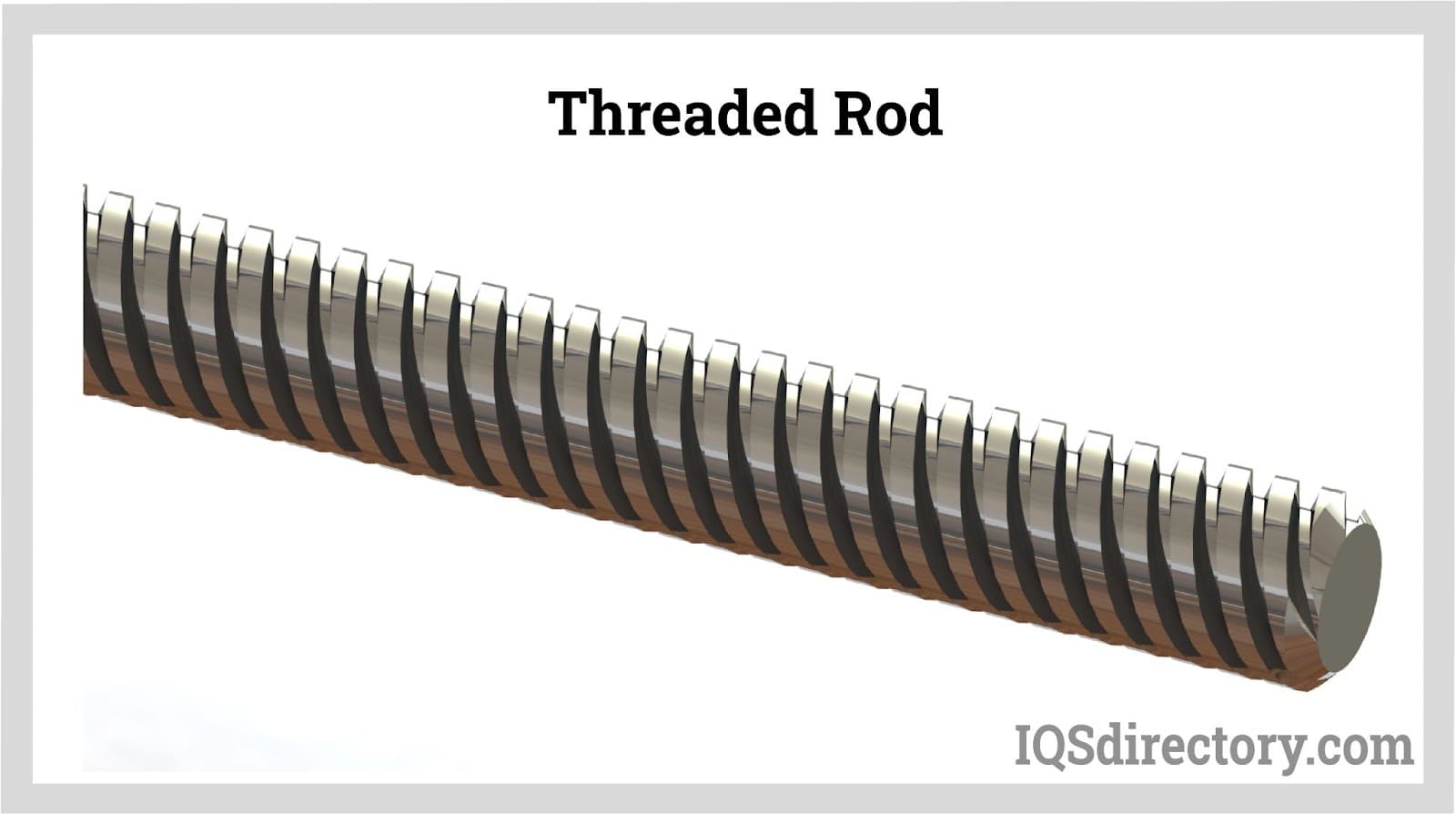

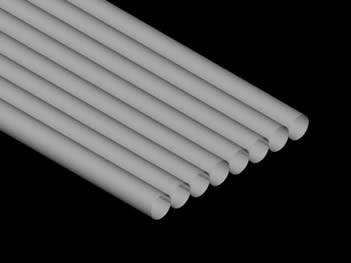

As the name implies, a threaded rod is a metal rod that has threads running the entire length of it. These rods have a screw-like appearance, although they are often longer and thicker than a typical screw. Unlike screw-on bolts, threaded rods do not have heads or washers, and they frequently have the same diameter throughout their entire length. Read More…

H & R Screw Machine Products-ISO 9001-certified manufacturer of high-volume screw machine products for many industries. We also produce CNC turned parts and provide machining of customer supplied castings, forgings and stampings.

It is Thuro’s mission to be the leading choice for screw machine parts, and to offer our products at the highest quality and the lowest cost. Our team members dedicate themselves to ensuring that our customers receive the perfect part on time, every time.

Based out of California, Pacific West America, Inc. (PWA) is a metal fabrication company. We focus most of our efforts on swiss screw machining, stampings, and precision parts, and our electronics division makes products such as cable assemblies, connectors, circuit boards and membrane switches. We create our products using a variety of CNC controlled machines, processes and robotics. Such...

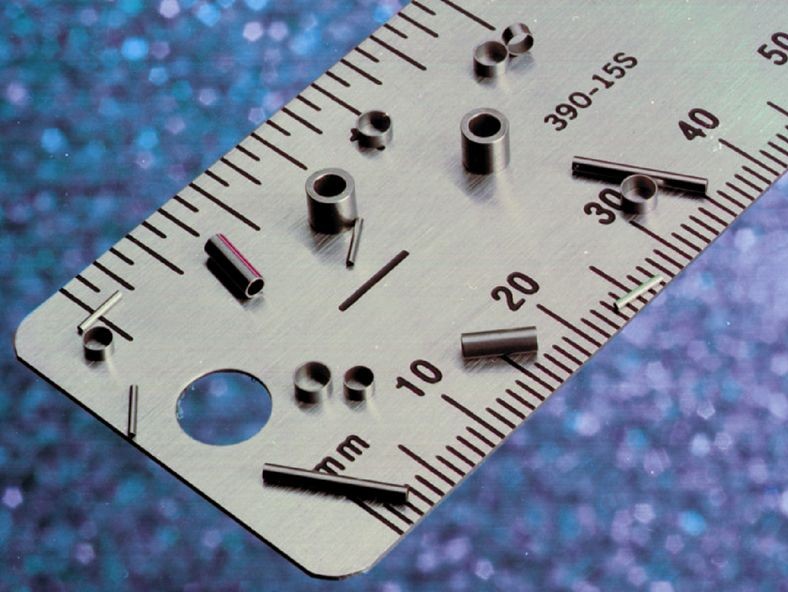

ISO Certified Precision Multi-Spindle Screw machining since 1905 with over 40 Davenports, CNC & Swiss machines. Made in the USA. We specialize in precision machined components such as screw machined nuts, threaded inserts, compression limiters, washers, bushings, fittings, pins, spacers, shafts…Low to high volume production with design support. The top industries we provide to are automotive,...

At M.A.R.'s Engineering, we take great pride in our ability to deliver high-quality screw machine products. Our screw machines are capable of producing complex components with utmost precision and efficiency. Whether it's small parts or intricate assemblies, we have the expertise and equipment to meet your specific requirements. With a wide range of materials and finishes available, we can...

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

As ATD Precision, we specialize in providing high-quality screw machine products to meet the diverse needs of our customers across various industries. With years of experience and expertise in precision machining, we offer a wide range of services tailored to deliver precise and reliable components. Our team of skilled machinists and engineers utilizes state-of-the-art equipment and advanced...

C.E. Holden, Inc. has been producing the finest quality screw machine products since 1950. Over the years, we have provided our customers in Pittsburgh and worldwide with a tremendous assortment of parts and components including specialty screw machine work. The capacity of our screw machines is from 1/8 to 1 inch round and up to 4 inches long, profiled bar stock up to 1 inch in diameter.

More Threaded Rod Manufacturers

Usually, carbon-coated, zinc-coated, or stainless steel is used to make it. Bolts and other fasteners can be attached to the rod using the threading to accommodate a variety of building applications. Threaded rod is frequently used to make a link between two materials, such as concrete and another object or two objects made of metal or wood.

How Threaded Rods are Made

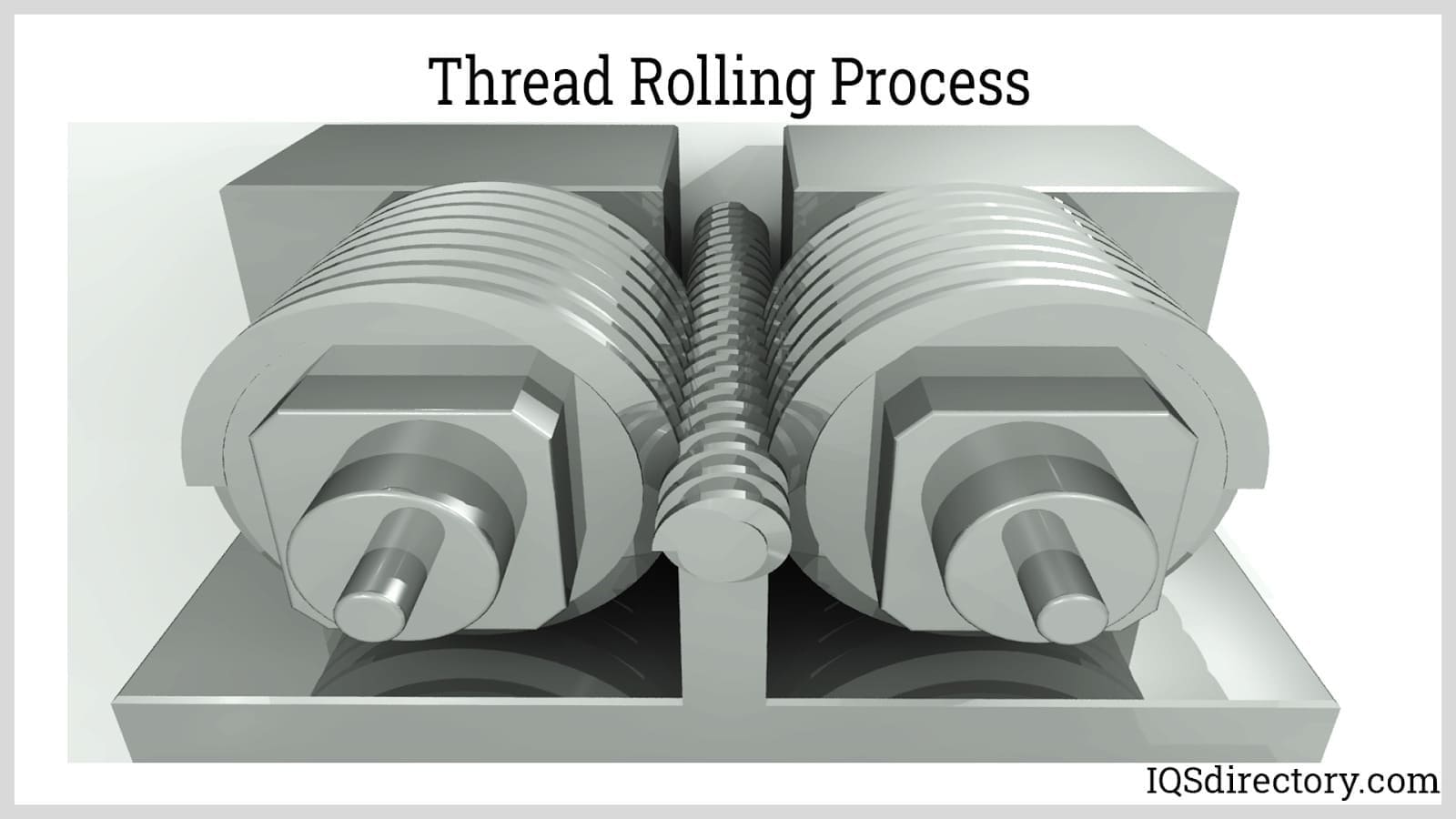

Round bar with the correct grade and diameter is used to create a threaded rod. A thread rolling machine will often be used to mass produce threaded rod of a standard diameter and grade. Round bar is passed through two hardened-steel rollers during this procedure to imprint the thread onto the bar.

The incredibly high pressures applied by these rollers, which are spaced apart precisely and rotate perpendicularly to the direction the round bar is being passed through them, transform the round bar into a threaded bar. The round bar is pushed through the rollers in this largely automated process in order to imprint the thread into the surface. After being sawed to size, the threaded bar's edges are beveled to create a smooth finished surface.

Unusual threaded rod patterns are often produced through cutting. The circular bar is driven through a machine that removes the surface thread as it is forced along after being cut to a length that is just a little bit longer than intended. The threaded bar is next beveled and lengthened. This method costs more because it takes longer to complete than thread rolling. Depending on the intended use, threaded rod is most frequently constructed of carbon steel, mild steel that has been zinc-plated, or stainless steel.

Applications of Threaded Rods

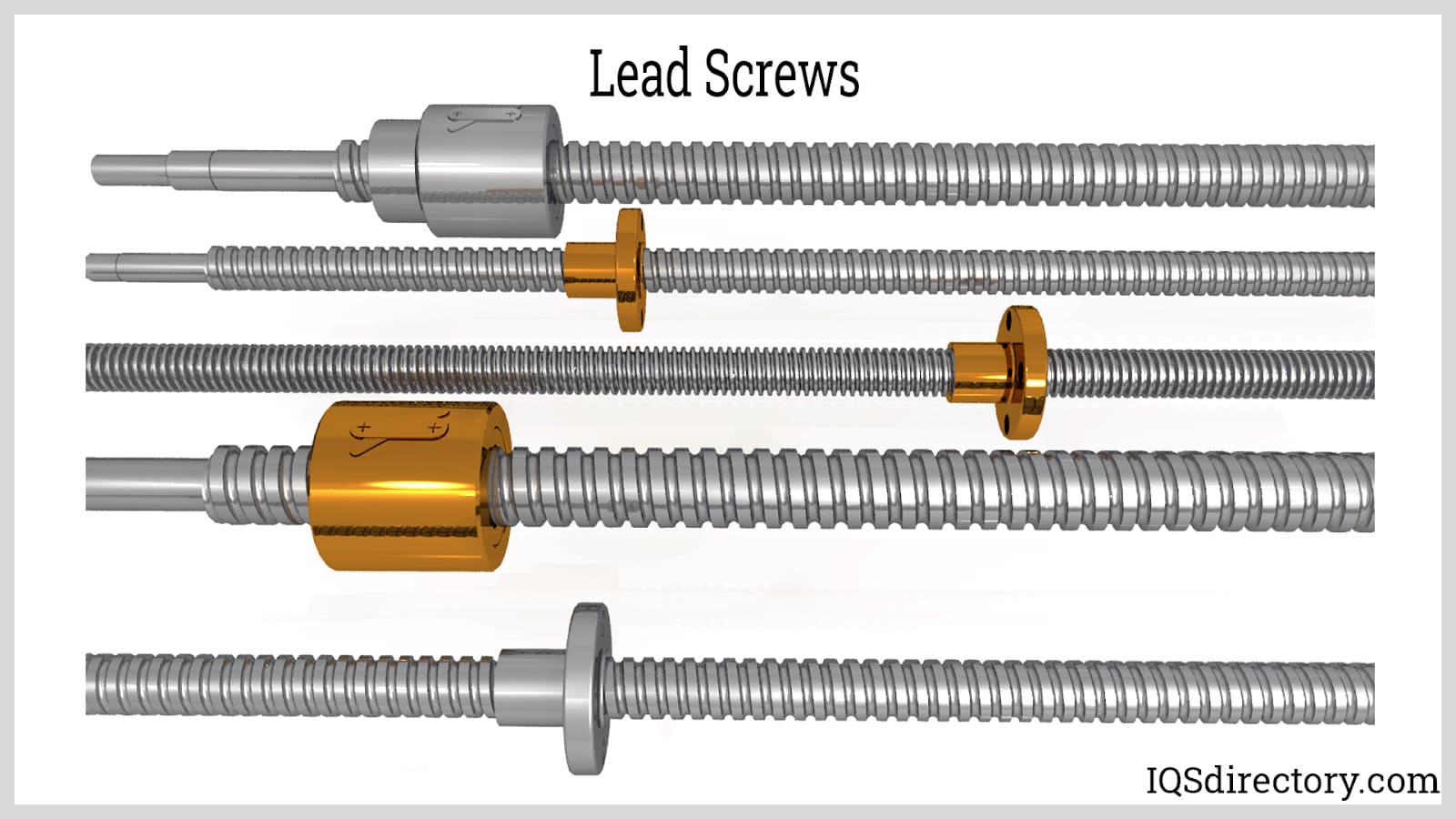

- When thinking about threaded rod, thread direction is another crucial parameter to take into account in addition to length, diameter, and material. Left-handed threads, albeit less common, tighten with counterclockwise rotation and are advantageous in situations where vibration would cause right-handed threads to become loosened. Right-handed threading is present on some rods, whereas left-handed threading is present on others. The threading peak of an acme has a square, flat surface; coarse and fine threads are also offered. Threaded rod has a wide range of applications across numerous areas.

- They are used to secure pieces together and make repairs in the manufacturing, automotive, and construction industries because they can be utilized with the majority of conventional fasteners and offer quick and easy disassembly or reassembly.

- Additionally, they are used for hobbies, plumbing, and electrical reasons. Threaded rods are used in a variety of applications due to their strength and ease of cutting and bending using standard equipment.

- The major application for threaded rods is when the required length or diameter exceeds that of the more typical bolts or screws. Threaded rods can be used whenever a large screw, bolt, or anchor bolt is utilized. It frequently serves this purpose in significant construction projects like bridges. Here, a threaded rod is employed since the length and diameter requirements are far greater than those for a standard bolt.

- By serving as a pin to connect the two materials, these fasteners can be utilized to bind metal or wood together.

- They can be used to stabilize everything from wooden furniture to concrete walls, and they are frequently placed into concrete or wood during repairs.

- When building homes or other sorts of constructions, builders and contractors may also employ threaded rods. When creating furniture or consumer goods, metalworkers frequently use these threaded studs.

Advantages of Using Threaded Rods

- In the marine industry, stainless steel rods can be utilized successfully without rusting or degrading. One of the primary advantages of stainless steel rods is their resistance to corrosion. Utilizing corrosion-resistant materials increases efficiency by preventing any potential harm from exposure to the elements.

- In terms of both tensile strength and corrosion resistance, threaded rods exhibit exceptional durability. Even under harsh situations, they are reusable and do not warp or bend. They can be fastened to any machine without concern for failure because of their dual strength and durability. This tensile strength makes them an excellent choice for a variety of applications. They are necessary tools in a variety of industries thanks to their resilience and adaptability.

Choosing the Correct Threaded Rod Manufacturer

To make sure you have the most productive outcome when purchasing threaded rods from a threaded rod manufacturer, it is important to compare at least 5 manufacturers using our list of threaded rod companies. Each threaded rod manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each threaded rod company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple companies with the same message.

Broaching

Broaching CNC Machining

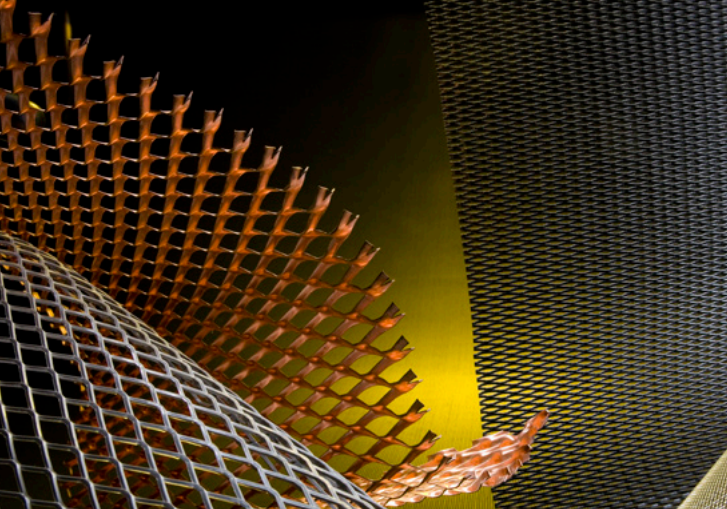

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

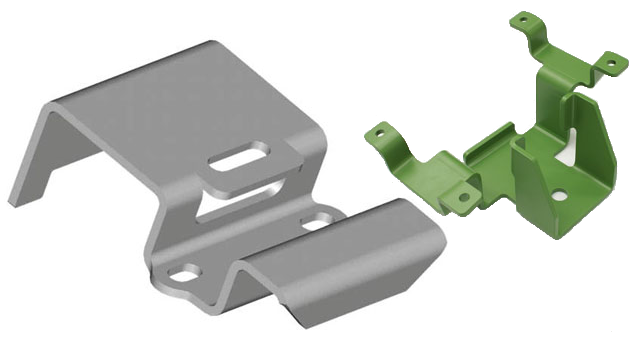

Metal Etching Metal Fabrication

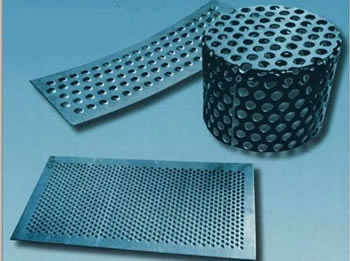

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

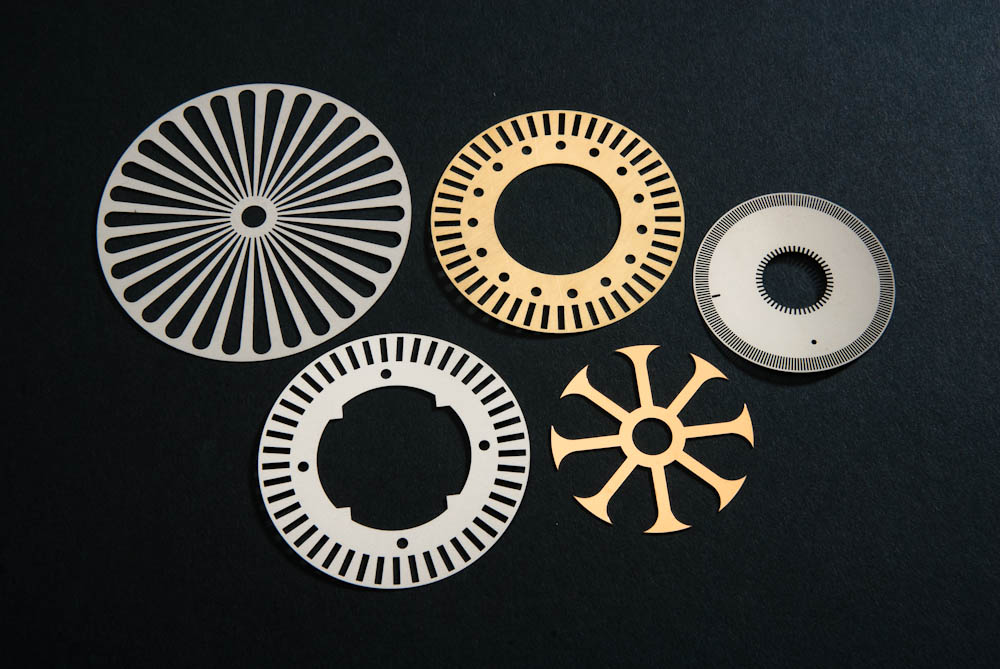

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services