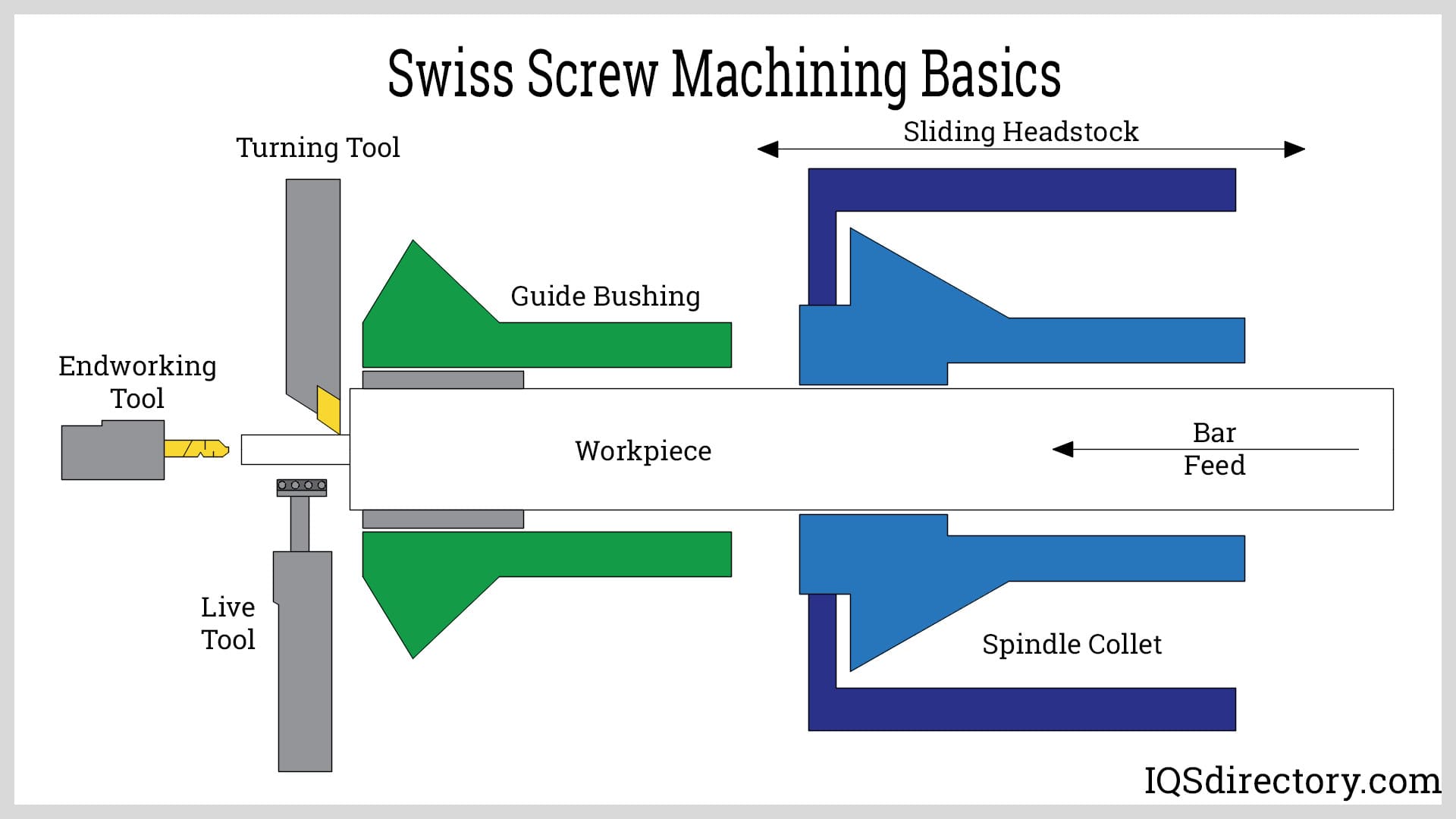

One of the most important innovations in lathe operation has been the development of the Swiss CNC screw machine that is capable of performing precise minute adjustments to a workpiece from multiple angles. Using a sliding headstock, materials can be rotated and moved longitudinally while tool holders move the workpiece forward and backward to make cuts and changes. Read More…

H & R Screw Machine Products-ISO 9001-certified manufacturer of high-volume screw machine products for many industries. We also produce CNC turned parts and provide machining of customer supplied castings, forgings and stampings.

It is Thuro’s mission to be the leading choice for screw machine parts, and to offer our products at the highest quality and the lowest cost. Our team members dedicate themselves to ensuring that our customers receive the perfect part on time, every time.

Based out of California, Pacific West America, Inc. (PWA) is a metal fabrication company. We focus most of our efforts on swiss screw machining, stampings, and precision parts, and our electronics division makes products such as cable assemblies, connectors, circuit boards and membrane switches. We create our products using a variety of CNC controlled machines, processes and robotics. Such...

At M.A.R.'s Engineering, we take great pride in our ability to deliver high-quality screw machine products. Our screw machines are capable of producing complex components with utmost precision and efficiency. Whether it's small parts or intricate assemblies, we have the expertise and equipment to meet your specific requirements. With a wide range of materials and finishes available, we can...

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Dynamic Machining X Manufacturing, LLC is a leading provider of precision machining services, specializing in medical machining, aerospace parts manufacturing, mill-turn center operations, 5-axis machining, and more. Our state-of-the-art facilities and highly skilled team enable us to deliver complex and intricate components with unparalleled accuracy and quality. Serving a wide range of...

At Lakeside Screw Products, we pride ourselves on delivering exceptional screw machine products crafted with precision and quality. Our commitment to excellence is ingrained in our rigorous quality control process, ensuring that every component we produce meets the highest standards of accuracy and reliability. Since 1977, Lakeside Screw Products has been a trusted partner, providing unparalleled ...

More Swiss CNC Screw Machine Product Manufacturers

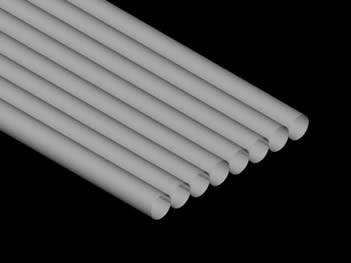

Swiss CNC Screw Machine Products

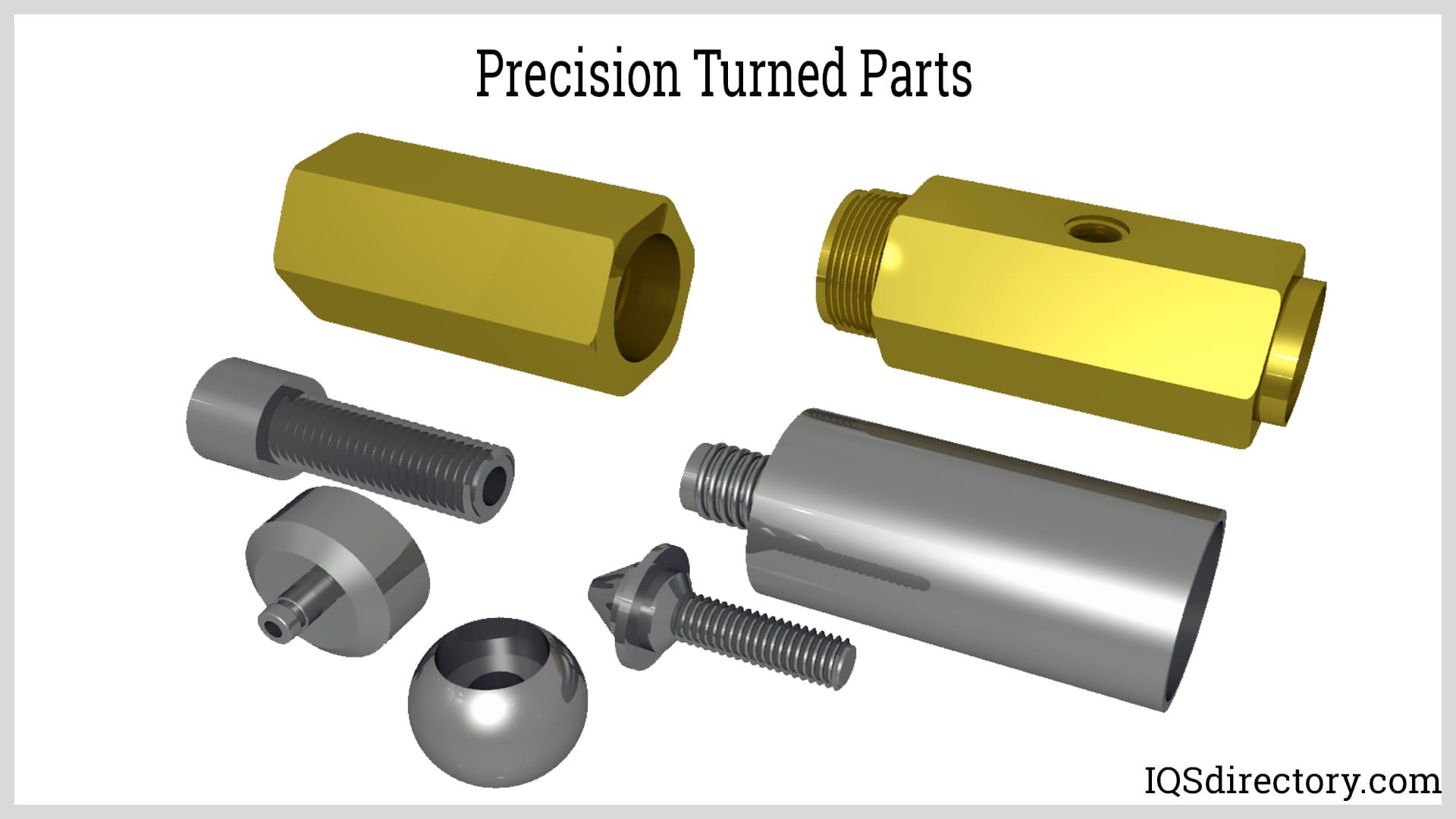

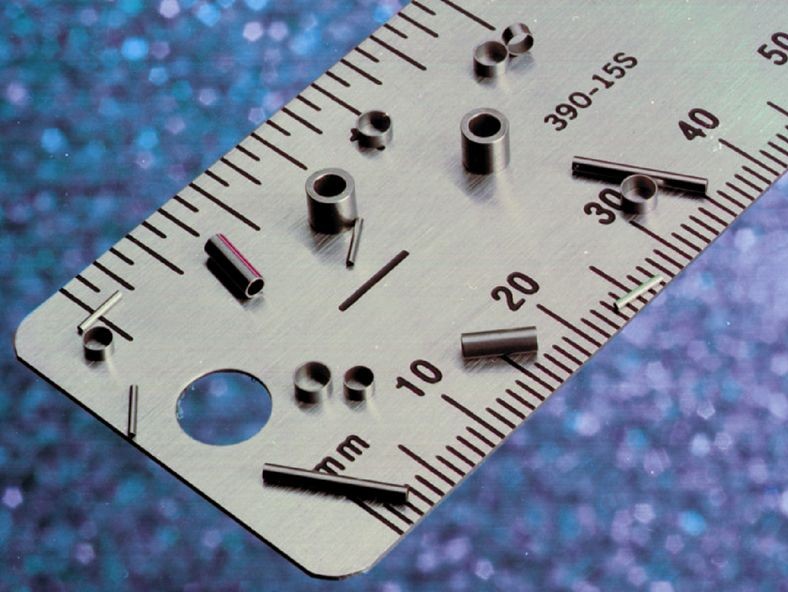

The benefit of a Swiss CNC screw machine is its ability to perform a series of adjustments in a short time period. Small parts, requiring intricate adjustments, can be efficiently and easily processed.

What are Swiss CNC Screw Machine Products?

Swiss CNC machines are relied on to make complicated cuts at varying levels and angles with accurate precision. There is an endless variety of Swiss CNC screw machine products, and the number of products is rapidly growing as new and unique uses are discovered.

Of the many industries that rely on the production of Swiss CNC screw machine products, the auto industry is at the top of the list. Auto production requires rapid movement and precision applications. Large quantities of parts are a necessity and have to be readily available. These are ideal conditions for the use of a Swiss CNC screw machine, as it quickly and accurately produces precision parts and components.

One of the fastest growing industries in the world of Swiss CNC screw machining is the electronics industry, which has a high demand for minute and intricate parts. Since Swiss CNC screw machine products cover the full spectrum, from normal to exceptionally unusual, the Swiss CNC screw machine method of production is a perfect fit for electronic industry requirements.

Materials Used to Make Swiss CNC Screw Machine Products

Swiss CNC screw machine products are produced on a Swiss CNC machine using a subtractive process where fragments of metal are removed from the workpiece to create the final product. This is unlike an additive process where pieces are added to the workpiece. There is a wide variety of metals that can be shaped using the CNC process. They include metals that are pliable, ductile, and formable.

When determining what metal to use to produce a Swiss CNC screw machine product, the easier task would be to decide which metals cannot be processed using the CNC screw machine method. Though a wide range of materials can be transformed using the CNC machine process, there are a select few that are more commonly used.

The most common metals shaped using Swiss CNC screw machines include aluminum, brass, and steel. Products made using aluminum are normally made of aluminum alloys. This is typically done to enhance the aluminum while taking advantage of its unique properties. Aluminum is exceptionally pliable and ductile and fits easily into the Swiss CNC machine process.

Brass is a combination of copper and zinc. It is an alloy that takes advantage of copper’s unique properties. The blending of copper and zinc to make brass creates a metal with an excellent appearance and the characteristics of copper. As with aluminum, it is very pliable and ductile with conductive properties.

Alloys of steel are commonly used; this allows utilization of steel’s strength and ruggedness. Swiss CNC screw machine products produced using steel have all of the strength, durability, and longevity of steel.

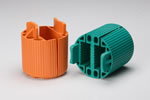

Though metals are normally thought to be the materials for Swiss CNC machining, other materials include plastics, wood, and certain varieties of foam. Swiss CNC screw machines have endless capabilities that can be used for any application.

The Benefits of Swiss CNC Screw Machine Products

Since its development in the middle of the first industrial revolution, Swiss CNC screw machining has rapidly grown to be the main method for producing intricate and complex components. The most compelling benefits are the speed at which products are produced and the accuracy with which they are produced.

Four of the main benefits of Swiss CNC screw machine products:

- Accuracy – Swiss CNC screw machine products are far more accurate than products produced using any other machining method.

- Speed – Since computers are used to control the CNC process, the speed of production is exceptional.

- Safety – Swiss CNC screw machines are far safer than any other process since they operate in a protected and enclosed area.

- Cost – With traditional machine operation, an operator is required for each machine. With Swiss CNC screw machine operation, one operator can oversee several machines.

Broaching

Broaching CNC Machining

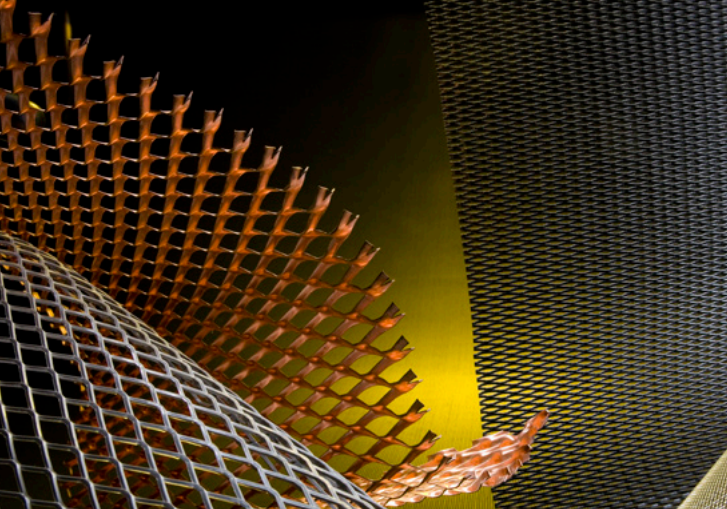

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

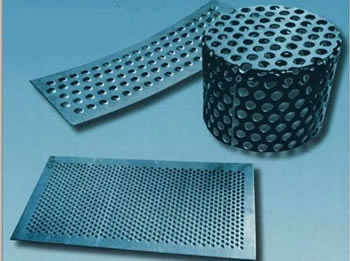

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

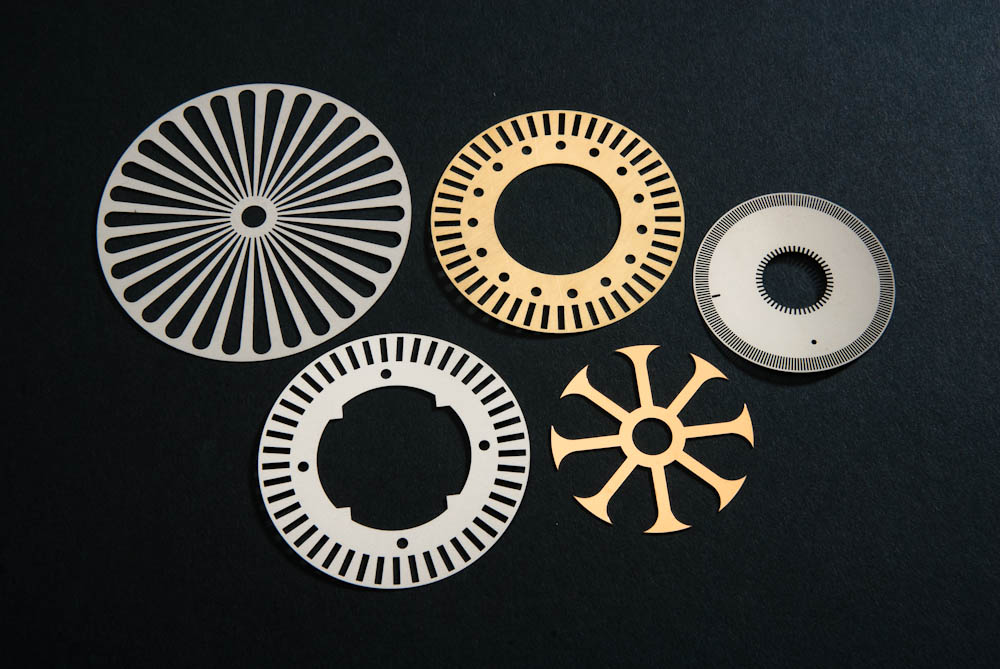

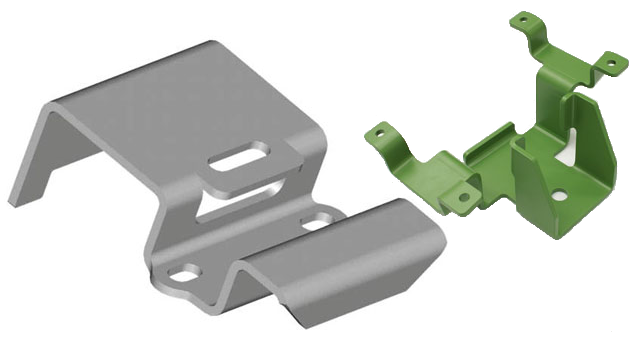

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services