Computer numerical control (CNC) turning minimizes the opportunity for human error and is able to produce parts that have been machined with a margin of error of less than 0.001 inch. Read More…

H & R Screw Machine Products-ISO 9001-certified manufacturer of high-volume screw machine products for many industries. We also produce CNC turned parts and provide machining of customer supplied castings, forgings and stampings.

It is Thuro’s mission to be the leading choice for screw machine parts, and to offer our products at the highest quality and the lowest cost. Our team members dedicate themselves to ensuring that our customers receive the perfect part on time, every time.

Based out of California, Pacific West America, Inc. (PWA) is a metal fabrication company. We focus most of our efforts on swiss screw machining, stampings, and precision parts, and our electronics division makes products such as cable assemblies, connectors, circuit boards and membrane switches. We create our products using a variety of CNC controlled machines, processes and robotics. Such...

At M.A.R.'s Engineering, we take great pride in our ability to deliver high-quality screw machine products. Our screw machines are capable of producing complex components with utmost precision and efficiency. Whether it's small parts or intricate assemblies, we have the expertise and equipment to meet your specific requirements. With a wide range of materials and finishes available, we can...

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Dynamic Machining X Manufacturing, LLC is a leading provider of precision machining services, specializing in medical machining, aerospace parts manufacturing, mill-turn center operations, 5-axis machining, and more. Our state-of-the-art facilities and highly skilled team enable us to deliver complex and intricate components with unparalleled accuracy and quality. Serving a wide range of...

At Lakeside Screw Products, we pride ourselves on delivering exceptional screw machine products crafted with precision and quality. Our commitment to excellence is ingrained in our rigorous quality control process, ensuring that every component we produce meets the highest standards of accuracy and reliability. Since 1977, Lakeside Screw Products has been a trusted partner, providing unparalleled ...

More Precision Turning Manufacturers

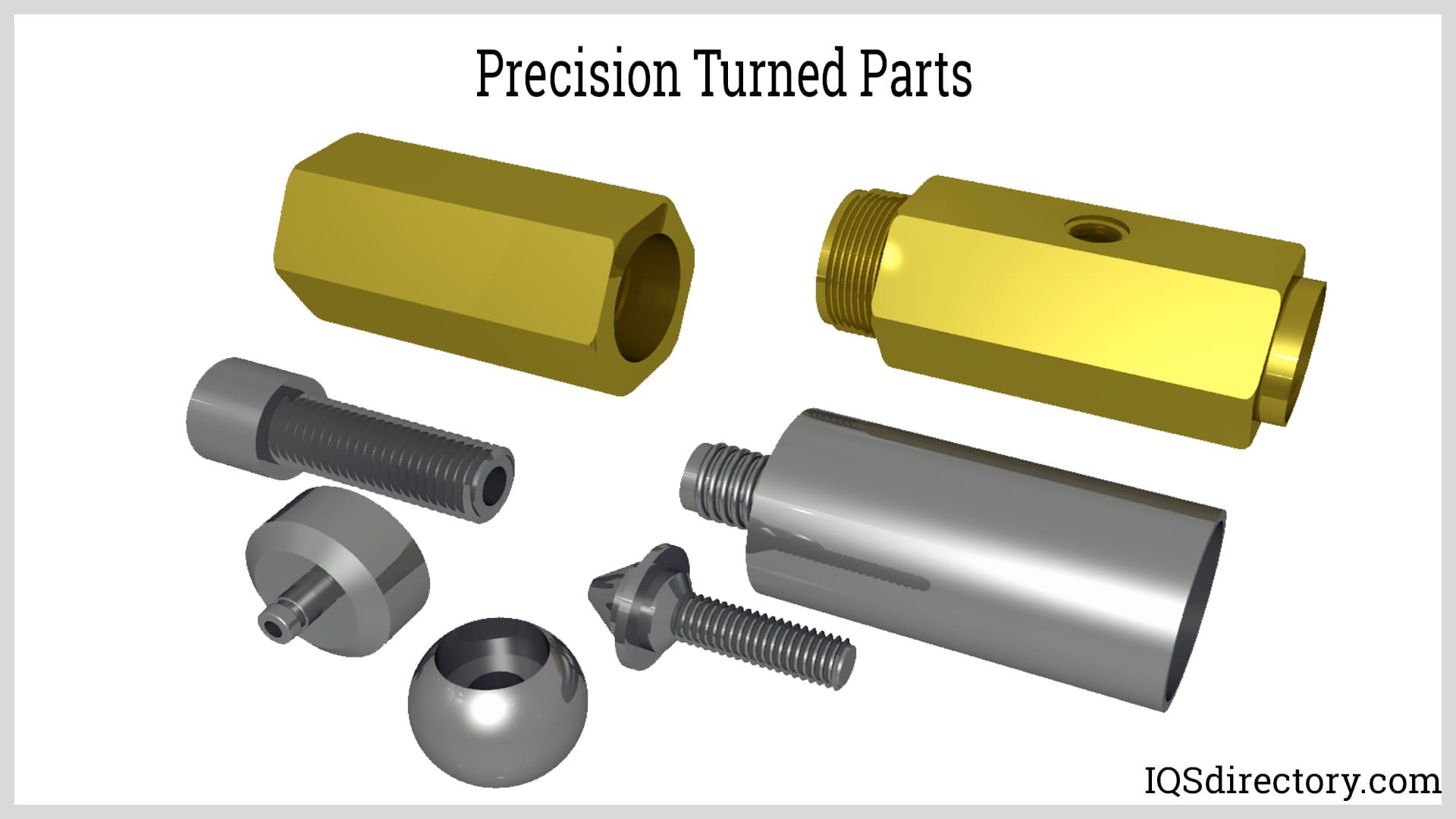

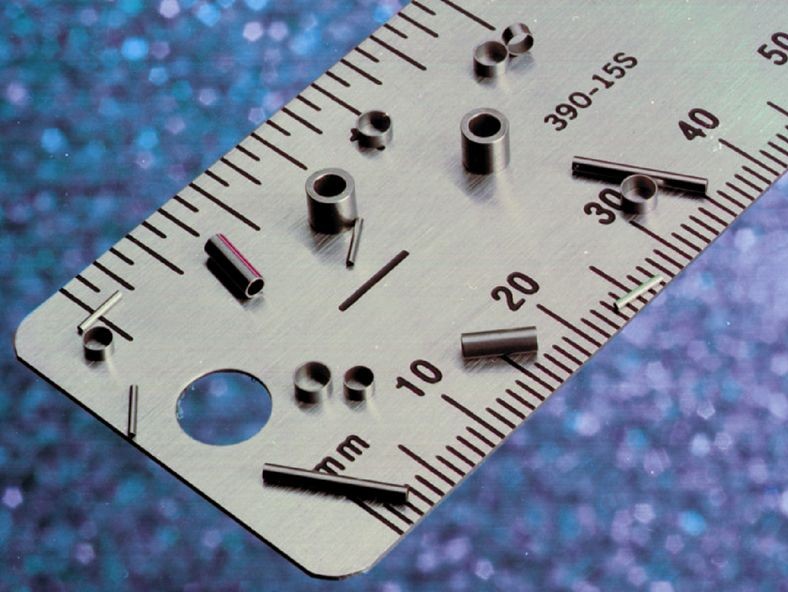

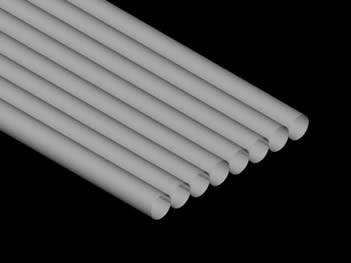

Precision turned parts are cylindrical and machined from aluminum, titanium, brass, stainless steel, copper, polycarbonate, nylon and polyvinyl chloride (PVC). Though cylindrical, these parts have many variations; for instance, the general shape may be contoured, fillet, tapered or pointed. They may receive a smooth finishing or be given a textured surface. Precision turning is critical for many parts to guarantee that they fit together and will function correctly; in some applications, even a small flaw or error can throw off the whole system, wasting valuable time and money.

Parts that are machined to very precise specifications will perform to higher standards. The demand for top quality parts is high; precision turning is an important process for parts such as rods, shafts, hubs, pulleys, bushings, couplings, housing, flanges, nozzles, tools and more. Precision turned parts are used in applications across many industries including the automotive, commercial, electronics, petroleum, defense, aerospace, marine and construction industries.

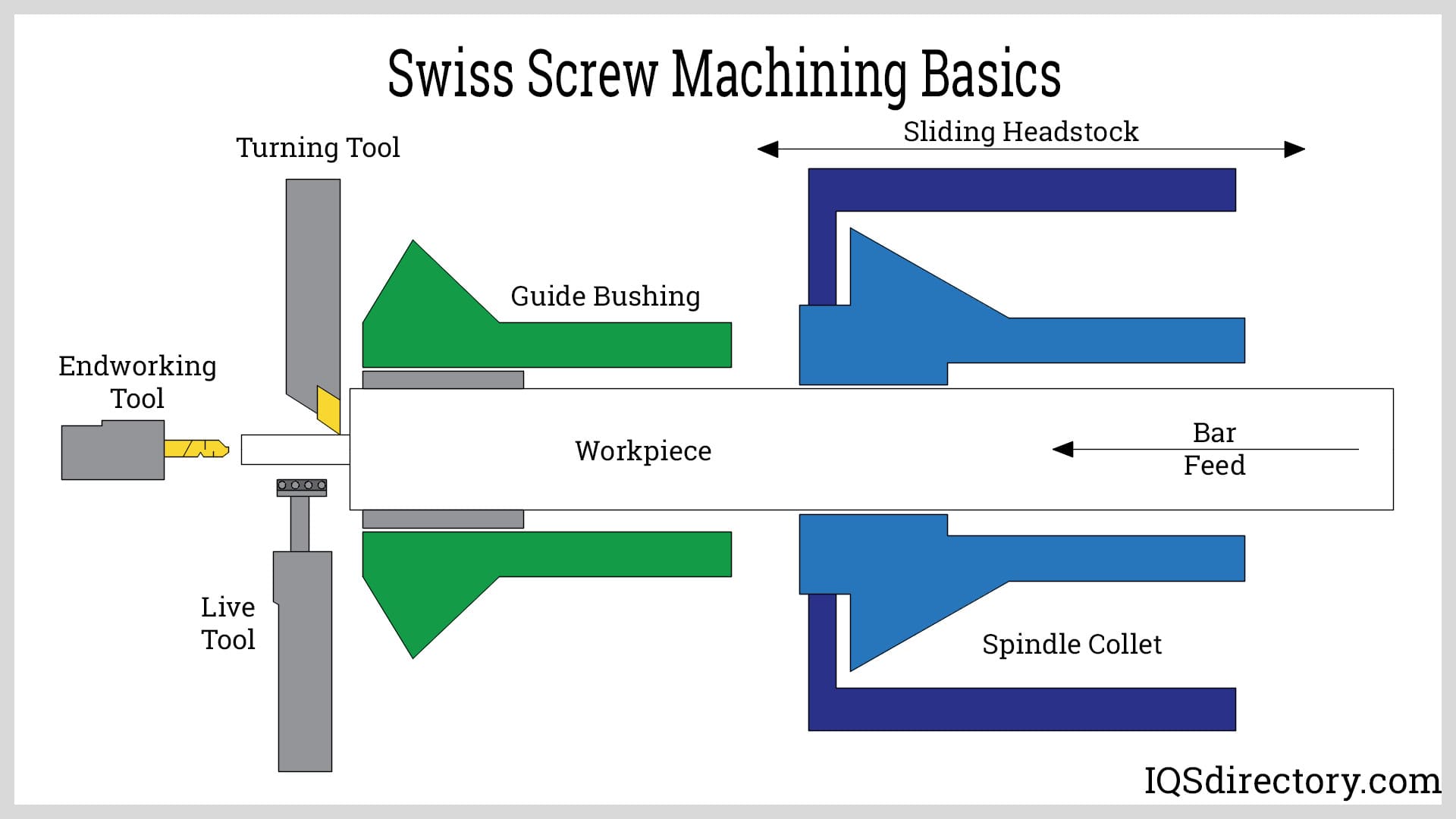

Precision turning is a fairly simple process. Computer-controlled turning is performed in machine shops. A round, square or hexagonal blank called a workpiece is attached to spindles on the machine that hold it firmly in place. The blank begins to spin and as it rotates, multiple automated cutting, drilling, notching and knurling tools attached to the machine apply the appropriate amount of pressure to shear away the material. The tools are powered by a motor located at the machine's base that acts as the power source for all operations.

These motors vary in horsepower in accordance with the size of the machine, the necessary speed and the material of the workpiece. Smoothing and finishing is completed and the part is removed from the machine. There is one major difference between turned and milled parts. During the machining process, turned parts are rotated and a stationary tool is applied whereas milled parts are held stationary while a tool rotates. There are two main pieces of equipment used to produce precision turned parts: screw machines or lathes. Both work in similar ways and are generally computer operated.

Screw machines have multiple spindles, which allows for the simultaneous machining of several parts. Lathes use a single spindle and a drill bit to cut away unnecessary material. CNC turning machines are quickly replacing conventional machines that require an operator with high levels of skill, knowledge and experience.

Broaching

Broaching CNC Machining

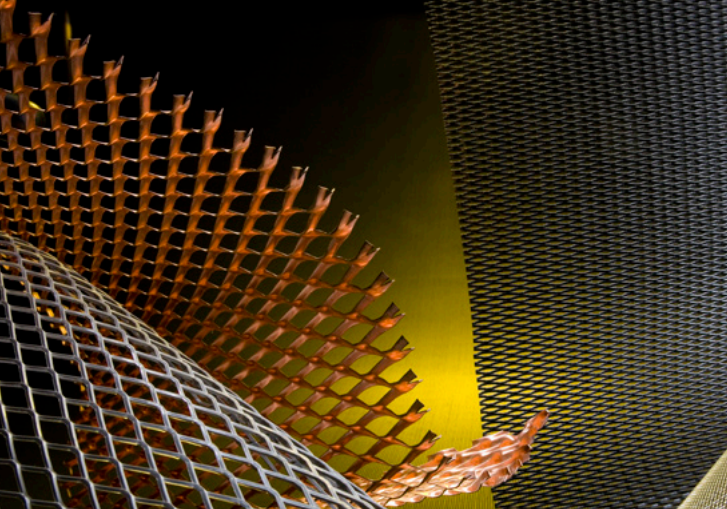

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

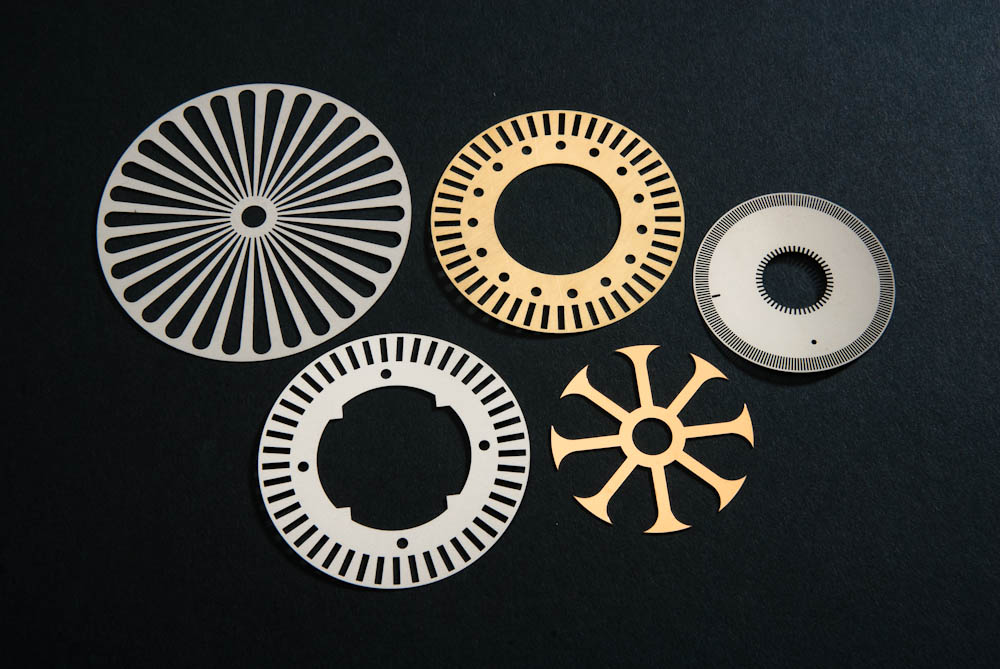

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

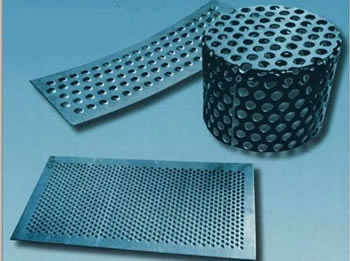

Metal Fabrication Perforated Metals

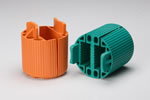

Perforated Metals Screw Machine Products

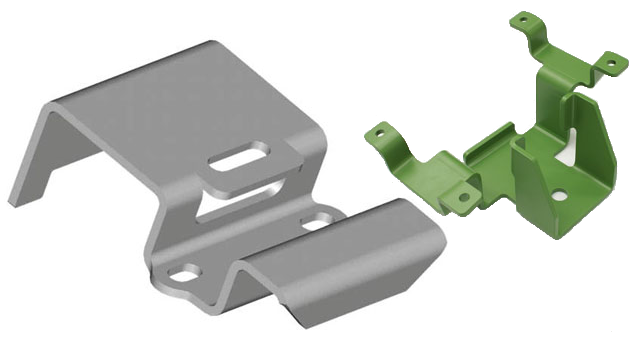

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services