Peak Precision

Peak PrecisionRequest A Quote

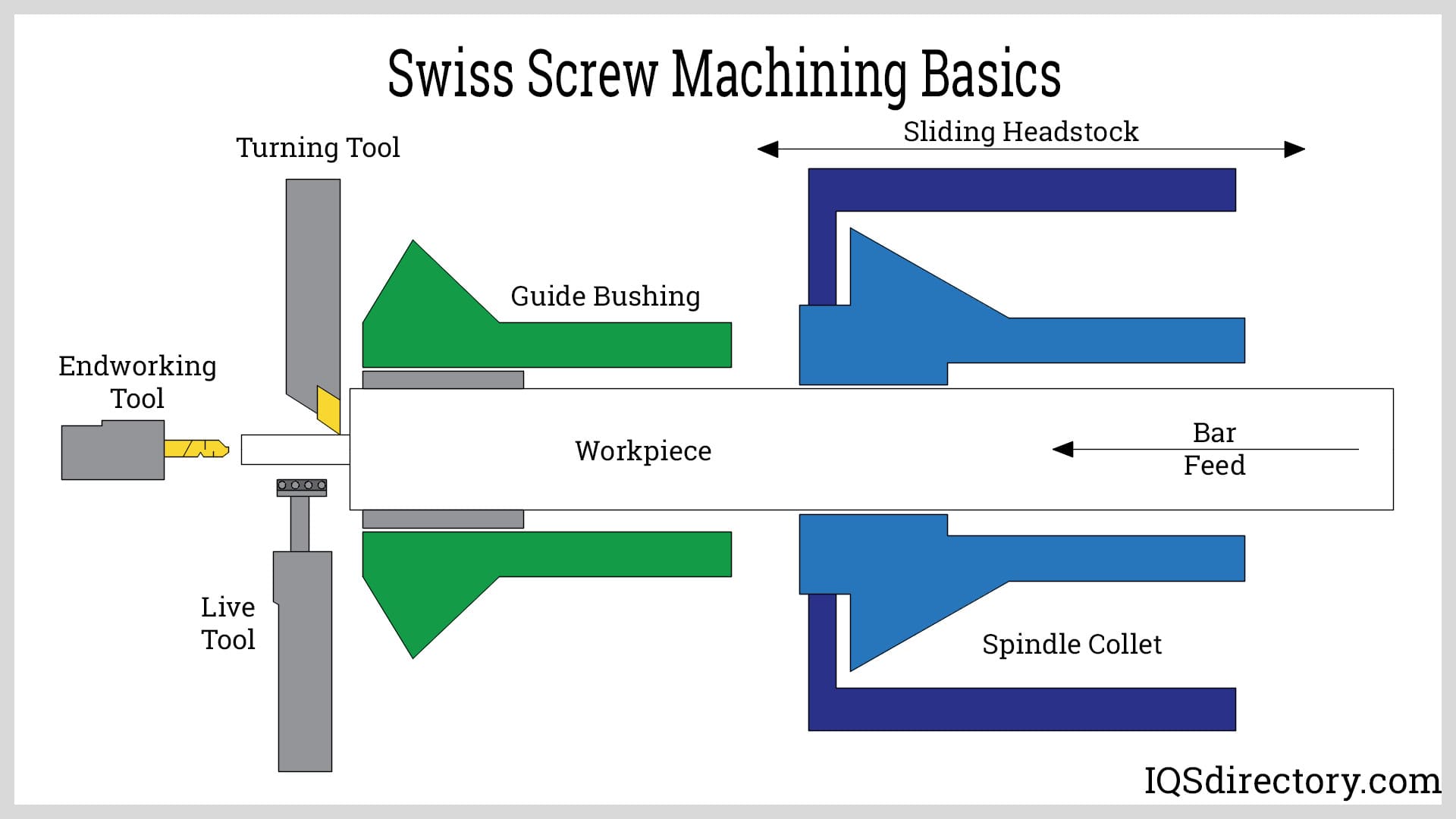

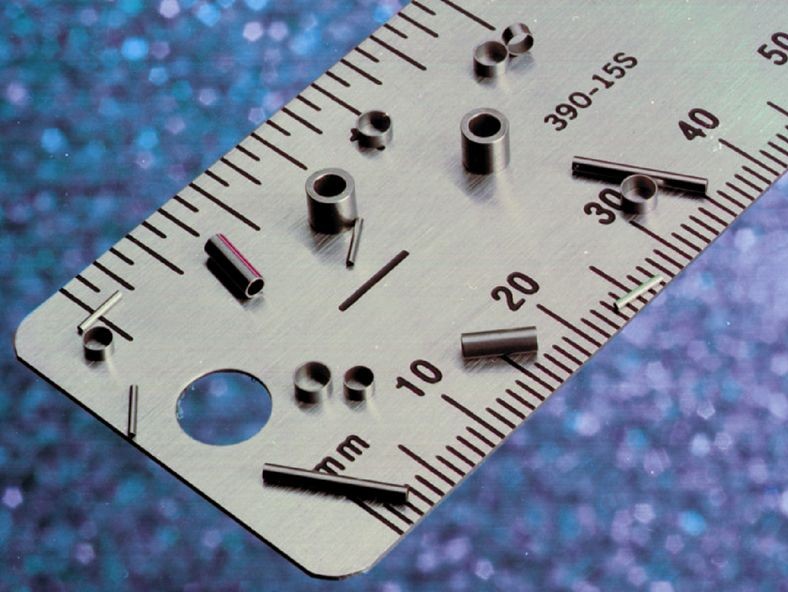

Hatfield, PAPeak Precision is a leading manufacturer and provider of high-quality Screw Machine Products. With a strong commitment to precision, reliability, and customer satisfaction, we have established ourselves as a trusted name in the industry. Our extensive experience, state-of-the-art facilities, and skilled workforce enable us to deliver exceptional screw machine products and services to a wide range of industries. Product Portfolio: At Peak Precision, we specialize in the production of screw machine products, catering to various specifications and requirements. Our comprehensive product portfolio includes a diverse range of precision components, such as screws, bolts, studs, spacers, fittings, connectors, and more. We work with a variety of materials, including steel, stainless steel, aluminum, brass, and other alloys, ensuring that our products meet the highest standards of quality and durability. Service Capabilities: 1. Customization: We understand that each customer may have unique requirements. Our team of skilled engineers and technicians collaborate closely with clients to develop customized screw machine products that precisely meet their specifications. From design and prototyping to production and delivery, we offer comprehensive customization services to ensure customer satisfaction. 2. Precision Machining: Our advanced machining capabilities allow us to achieve high levels of precision in the manufacturing process. We utilize cutting-edge CNC (Computer Numerical Control) machines, automatic lathes, and multi-spindle screw machines to produce intricate components with tight tolerances. Our skilled machinists meticulously monitor every step of the production process to ensure the accuracy and quality of the finished products. 3. Quality Assurance: At Peak Precision, quality is our top priority. We have implemented a rigorous quality control system that adheres to international standards and best practices. From raw material inspection to final product testing, we employ a range of quality assurance measures to ensure that our screw machine products meet or exceed customer expectations. 4. Fast Turnaround: We understand the importance of timely delivery in today's fast-paced business environment. With streamlined processes and efficient production techniques, we strive to provide quick turnaround times without compromising on quality. Our agile manufacturing capabilities enable us to fulfill both small and large orders promptly. 5. Value-Added Services: In addition to our core screw machine product offerings, we provide various value-added services to enhance customer satisfaction. These include secondary operations such as threading, knurling, milling, drilling, and deburring. We also offer finishing options such as plating, coating, and heat treatment to meet specific customer requirements. Industries Served: Peak Precision serves a diverse range of industries, including automotive, aerospace, electronics, telecommunications, medical devices, consumer goods, and more. Our products find applications in critical components and assemblies across these sectors, where precision, reliability, and durability are paramount. Conclusion: With a commitment to precision, quality, and customer satisfaction, Peak Precision is a trusted provider of screw machine products. Our extensive product portfolio, customization capabilities, precision machining, stringent quality assurance, fast turnaround, and value-added services make us the preferred choice for businesses across industries. Partner with us for your screw machine product needs and experience the Peak Precision advantage.

Broaching

Broaching CNC Machining

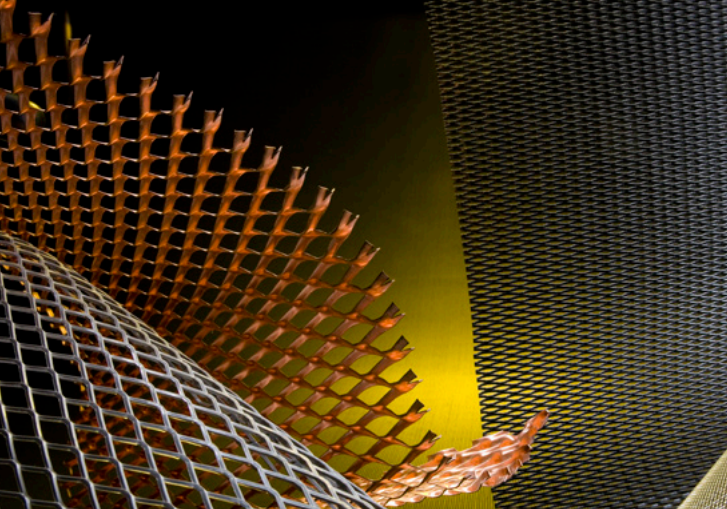

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

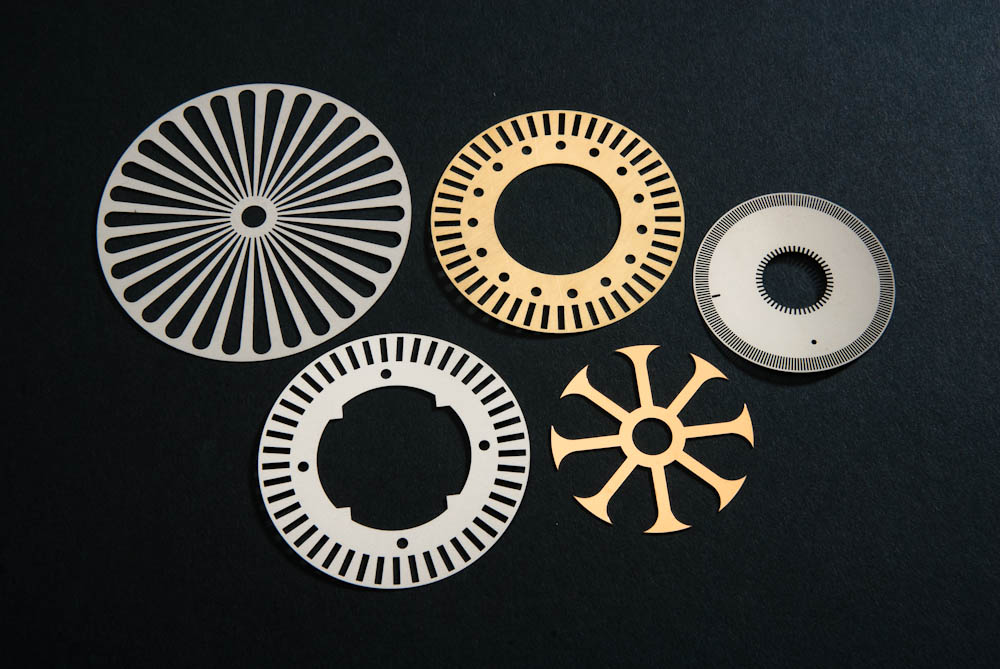

Laser Cutting Metal Etching

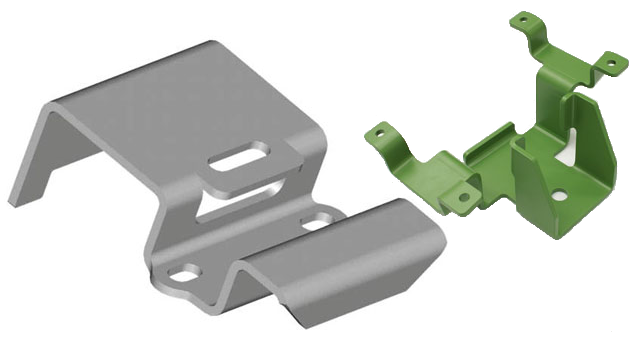

Metal Etching Metal Fabrication

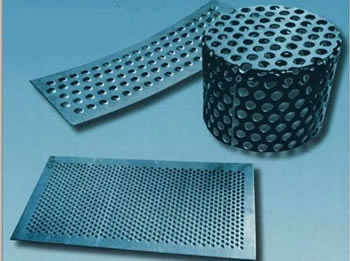

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services