Cass Precision Machining

Cass Precision MachiningRequest A Quote

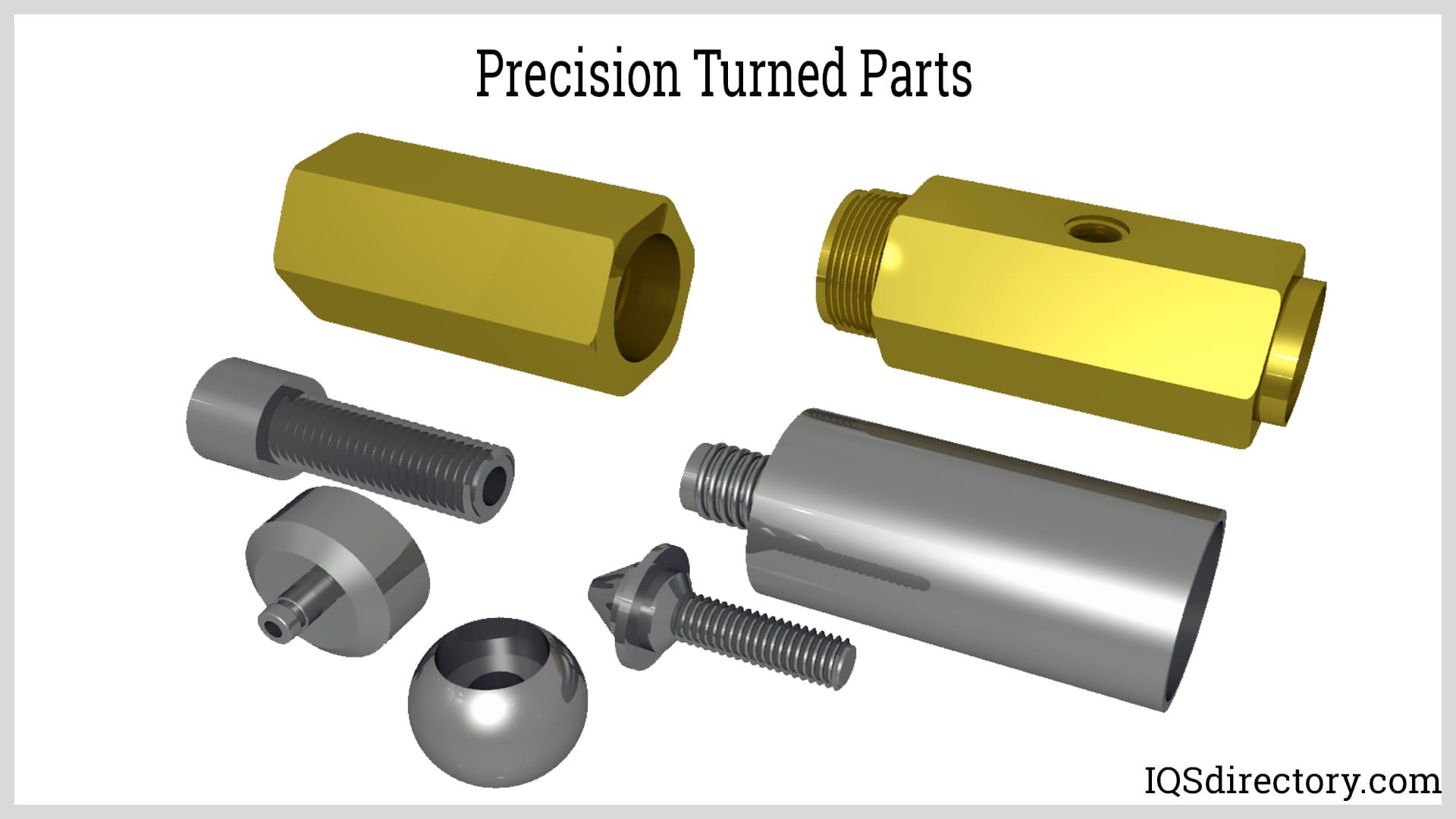

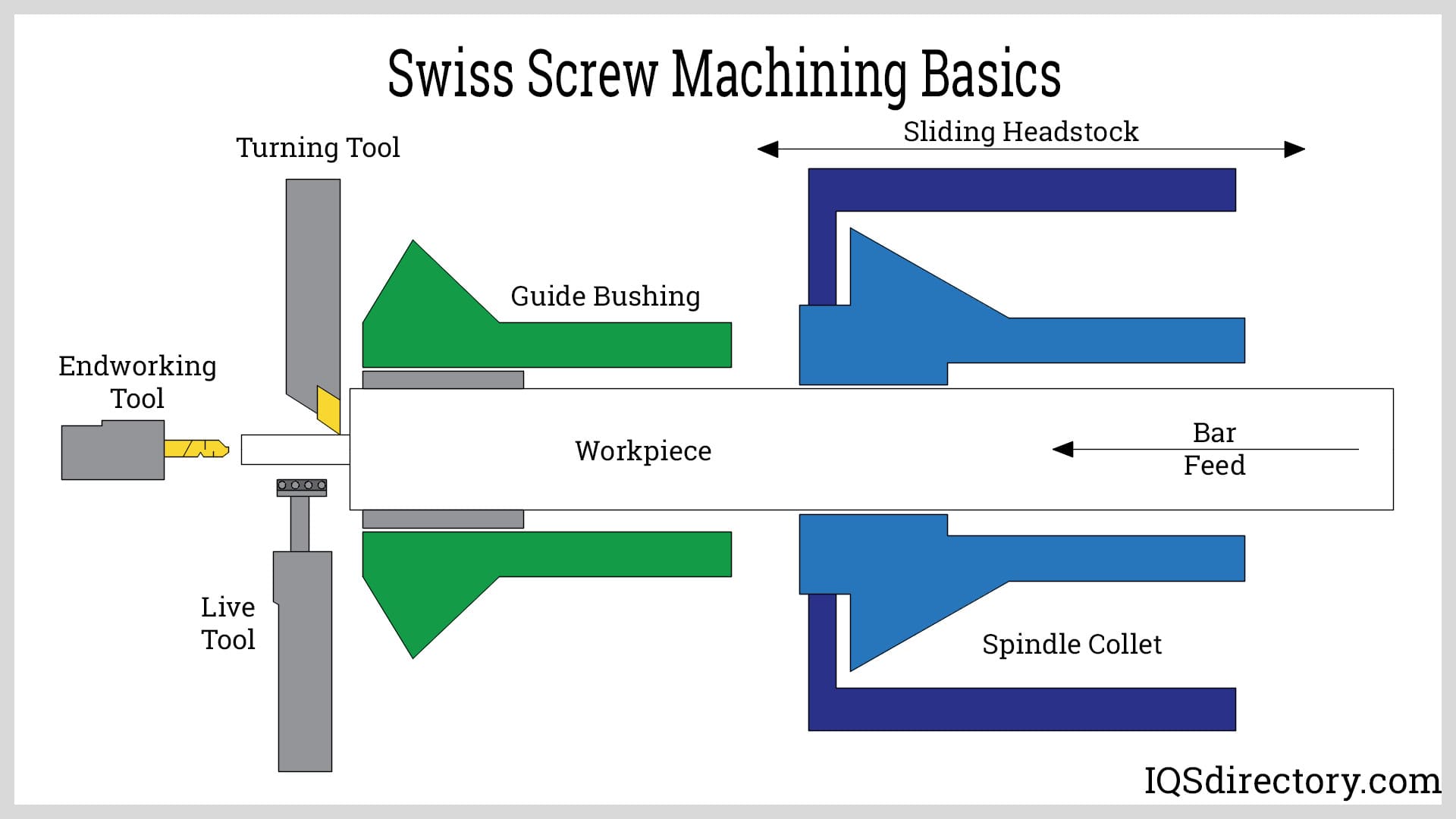

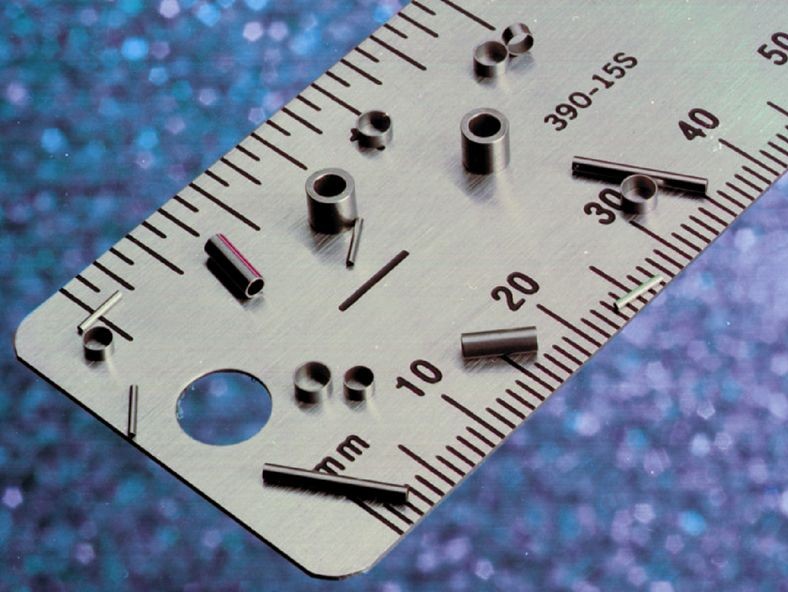

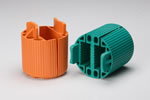

Brooklyn Center, MNCass Precision Machining is a leading provider of high-quality precision machining solutions, specializing in Screw Machine Products. With a strong commitment to excellence and customer satisfaction, Cass Precision Machining has established itself as a trusted partner in the manufacturing industry. Screw Machine Products: Cass Precision Machining offers a comprehensive range of Screw Machine Products, designed to meet the unique needs and specifications of various industries. Leveraging state-of-the-art technology and a team of skilled professionals, the company excels in the production of precision components, parts, and assemblies using screw machining techniques. Screw machining is a highly efficient and cost-effective manufacturing process that enables the production of complex parts with tight tolerances, making it ideal for applications that require precision and reliability. Service Capabilities: 1. Custom Screw Machining: Cass Precision Machining has the expertise and capabilities to handle custom screw machining projects of varying complexities. Their team works closely with clients to understand their specific requirements and design custom solutions that meet their exact needs. Whether it's a small batch or a large-scale production run, Cass Precision Machining ensures consistent quality and accuracy in every component they produce. 2. Material Selection: The company is equipped to work with a wide range of materials, including metals such as aluminum, stainless steel, brass, and titanium, as well as various plastics. Their experienced engineers can provide guidance on material selection, taking into account factors such as strength, durability, and cost-effectiveness to ensure optimal performance and customer satisfaction. 3. Precision Engineering: Cass Precision Machining places a strong emphasis on precision engineering. Their advanced CNC (Computer Numerical Control) machines, along with meticulous quality control measures, enable them to achieve tight tolerances and exceptional accuracy in every component they manufacture. This precision ensures that the screw machine products meet the exact specifications and requirements of the customers. 4. Secondary Operations: In addition to screw machining, Cass Precision Machining offers a range of secondary operations to provide customers with complete manufacturing solutions. These operations include but are not limited to milling, drilling, tapping, thread rolling, broaching, and finishing processes such as deburring, polishing, and plating. By providing these additional services, the company simplifies the supply chain for their clients and delivers fully finished products. 5. Quality Assurance: Cass Precision Machining is committed to delivering products of the highest quality. They have implemented a rigorous quality management system that adheres to industry standards and regulations. With a dedicated quality control team and advanced inspection equipment, the company ensures that every component undergoes thorough quality checks to meet or exceed customer expectations. 6. Timely Delivery: Recognizing the importance of prompt delivery in today's competitive market, Cass Precision Machining prioritizes efficient production processes and streamlined logistics. They have a track record of meeting tight deadlines and delivering products on time, helping their customers avoid costly delays and maintain their production schedules. Conclusion: Cass Precision Machining stands as a trusted partner for companies seeking reliable and high-quality Screw Machine Products. Their expertise in custom screw machining, precision engineering, secondary operations, and commitment to quality assurance enables them to deliver exceptional components and assemblies. With a customer-centric approach and a focus on innovation, Cass Precision Machining continues to drive manufacturing excellence in the industry.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

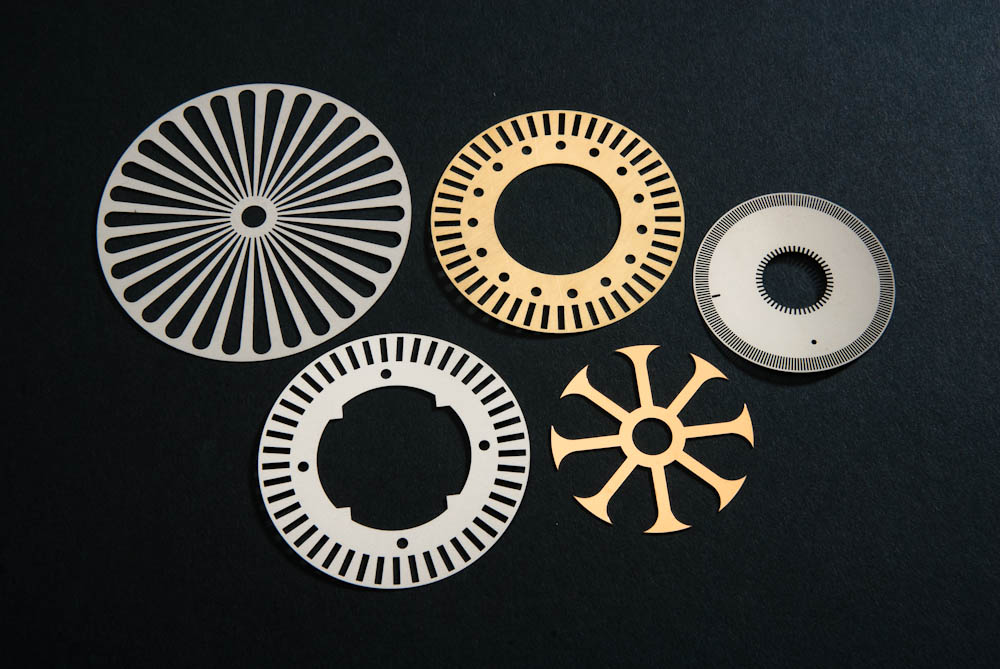

Laser Cutting Metal Etching

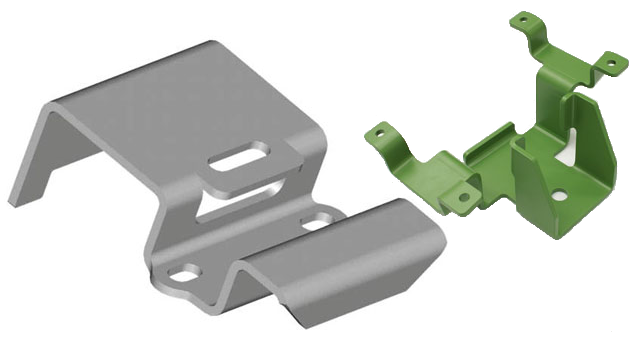

Metal Etching Metal Fabrication

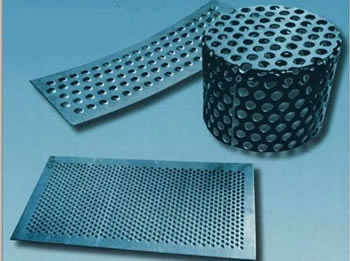

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services