Precision turning is performed via CNC turning, which can be done on CNC lathes or CNC screw machines. Multi-spindle CNC screw machines enable simultaneous processing of several items while attaining high-production rates. Read More…

H & R Screw Machine Products-ISO 9001-certified manufacturer of high-volume screw machine products for many industries. We also produce CNC turned parts and provide machining of customer supplied castings, forgings and stampings.

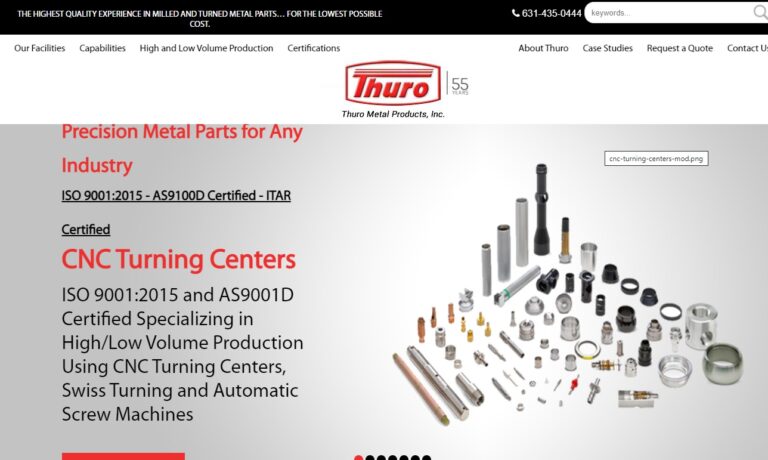

It is Thuro’s mission to be the leading choice for screw machine parts, and to offer our products at the highest quality and the lowest cost. Our team members dedicate themselves to ensuring that our customers receive the perfect part on time, every time.

Based out of California, Pacific West America, Inc. (PWA) is a metal fabrication company. We focus most of our efforts on swiss screw machining, stampings, and precision parts, and our electronics division makes products such as cable assemblies, connectors, circuit boards and membrane switches. We create our products using a variety of CNC controlled machines, processes and robotics. Such...

ISO Certified Precision Multi-Spindle Screw machining since 1905 with over 40 Davenports, CNC & Swiss machines. Made in the USA. We specialize in precision machined components such as screw machined nuts, threaded inserts, compression limiters, washers, bushings, fittings, pins, spacers, shafts…Low to high volume production with design support. The top industries we provide to are automotive,...

At M.A.R.'s Engineering, we take great pride in our ability to deliver high-quality screw machine products. Our screw machines are capable of producing complex components with utmost precision and efficiency. Whether it's small parts or intricate assemblies, we have the expertise and equipment to meet your specific requirements. With a wide range of materials and finishes available, we can...

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

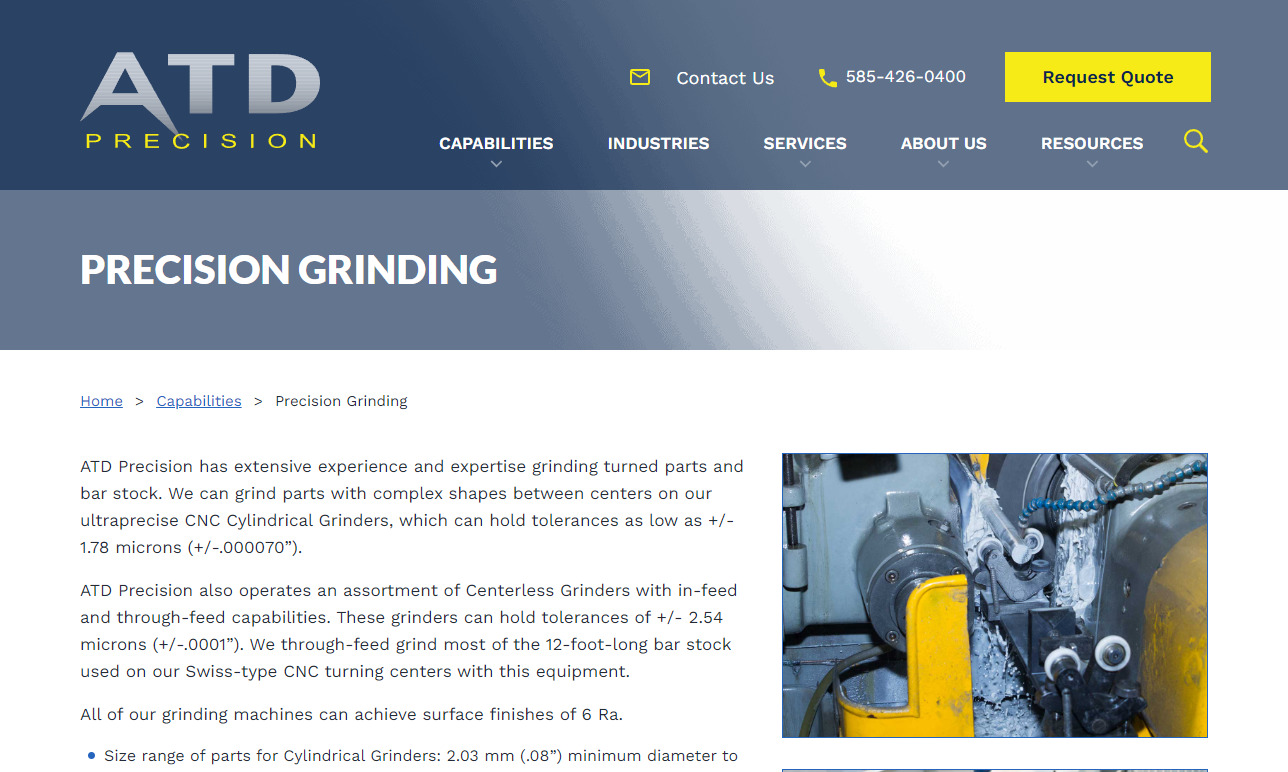

As ATD Precision, we specialize in providing high-quality screw machine products to meet the diverse needs of our customers across various industries. With years of experience and expertise in precision machining, we offer a wide range of services tailored to deliver precise and reliable components. Our team of skilled machinists and engineers utilizes state-of-the-art equipment and advanced...

C.E. Holden, Inc. has been producing the finest quality screw machine products since 1950. Over the years, we have provided our customers in Pittsburgh and worldwide with a tremendous assortment of parts and components including specialty screw machine work. The capacity of our screw machines is from 1/8 to 1 inch round and up to 4 inches long, profiled bar stock up to 1 inch in diameter.

More Precision Turned Part Manufacturers

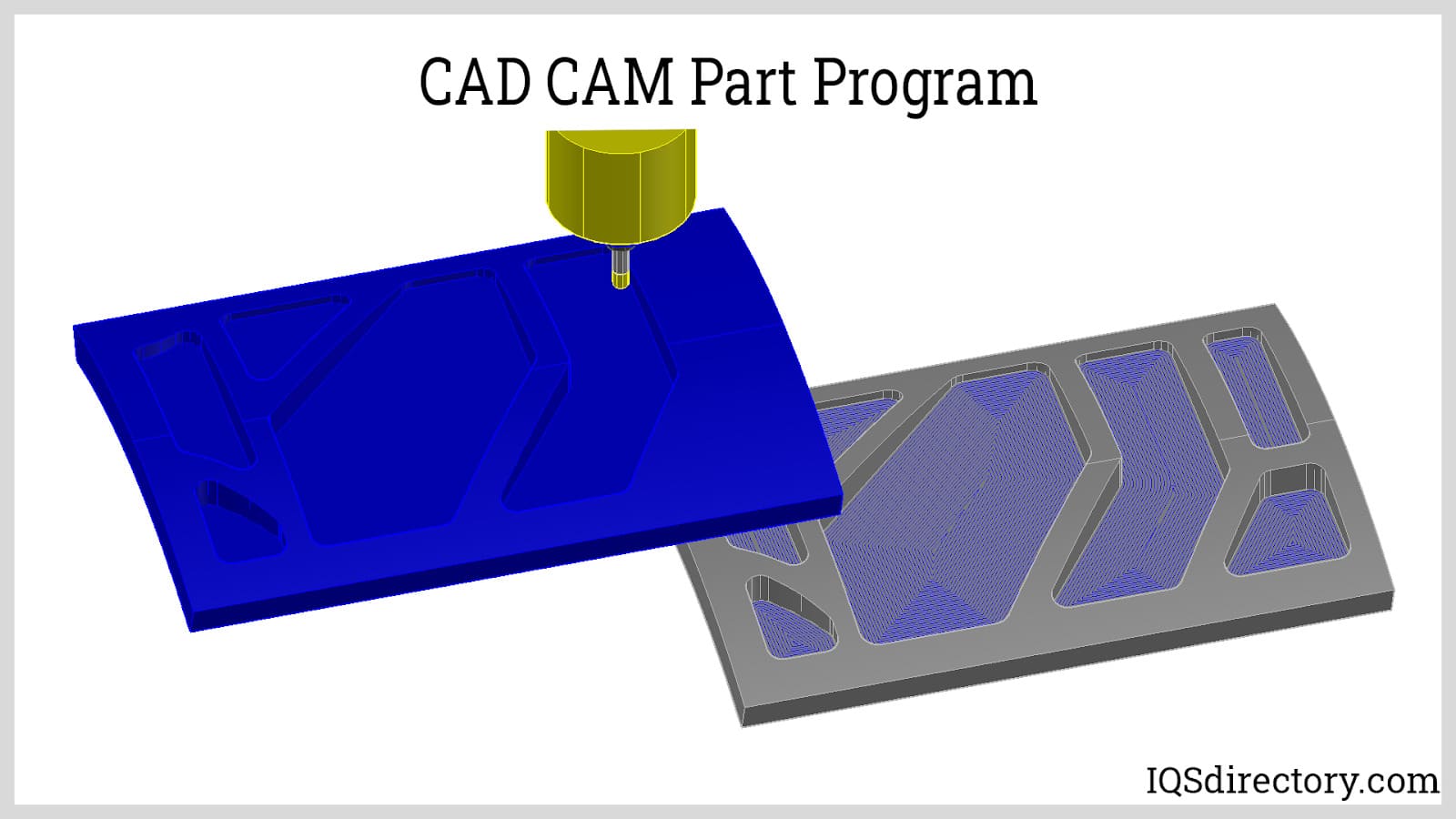

CNC Turning Process

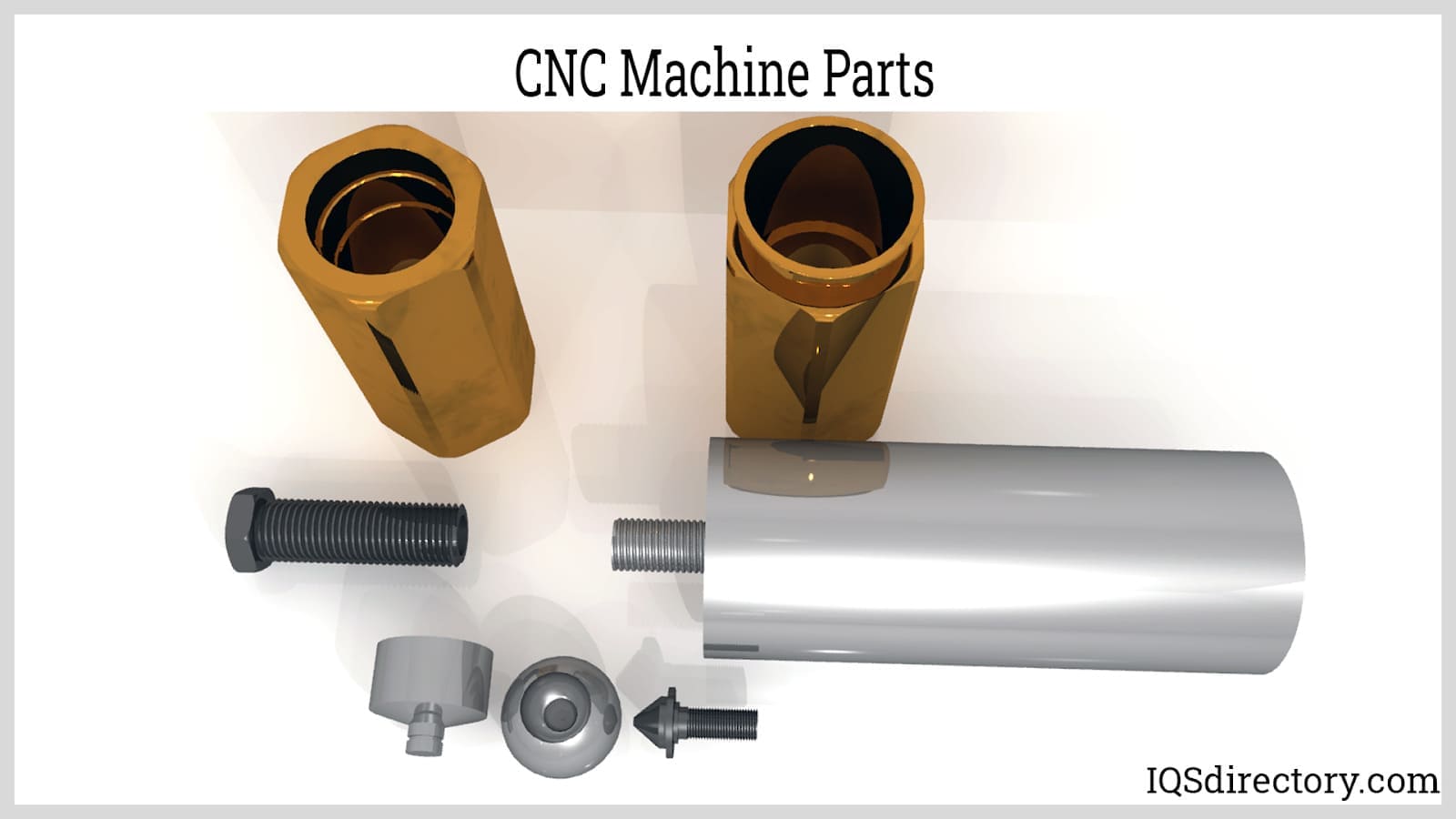

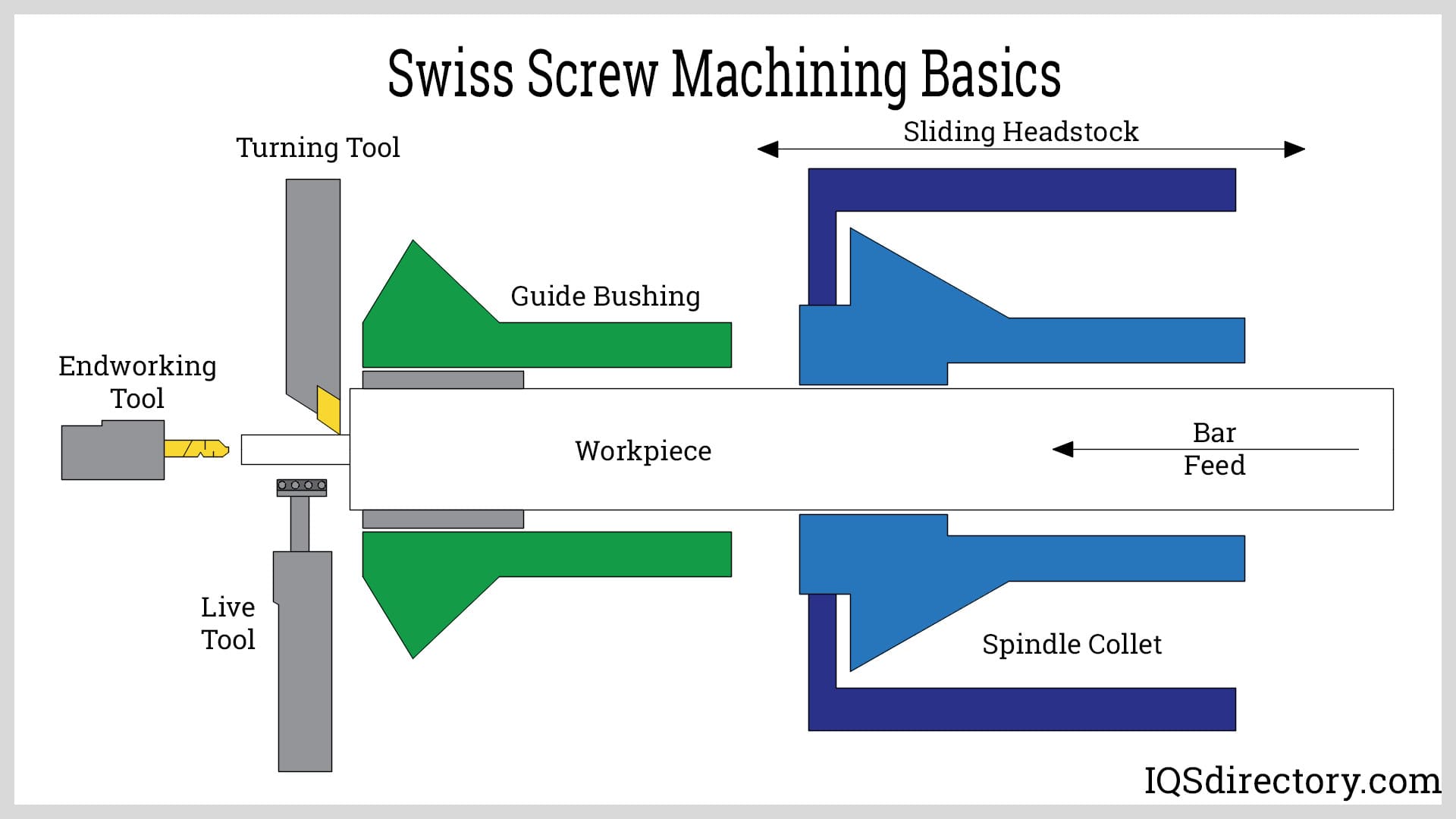

Turned parts offer extraordinary precision in terms of depth and dimensions thanks to novel turning methods that give design opportunities and structural advantages that cannot be profitably replicated with any other production method. After securing a round, square, or hexagonal blank to the spindle's spring sleeves, CNC machines are turned on.

The blank then starts to rotate while the machine's numerous automated cutting, drilling, notching, and knurling tools turn it into precision turned pieces by trimming the superfluous material, smoothing it out, and drilling. The Swiss screw machine's primary drive shaft powers the machine bed's main work shaft and manages the two front camshafts.

The engine of the machine, which is housed in the base of the machine, produces turned pieces, and its power varies based on the size, speed, material being processed, and the main power source for all operations. By holding and spinning a blank, also known as a workpiece, on a single spindle while the drill bit completes the cutting operation, a CNC lathe is a computer-controlled machine tool capable of creating precision turned parts.

In more recent developments, CNC lathes are rapidly replacing the earlier types of lathes because they are generally thought to be simpler to set up and run and because they require less in-depth lathe knowledge. Typically, the operator and setter are the same individual in factories that produce precision-turned parts.

Applications of Precision Turned Parts

- Materials utilized for precision turned parts include titanium, acrylic, brass, polycarbonate, nylon, copper, polyvinyl chloride (PVC), stainless steel, and aluminum, all of which can be created from even the most rigid of materials.

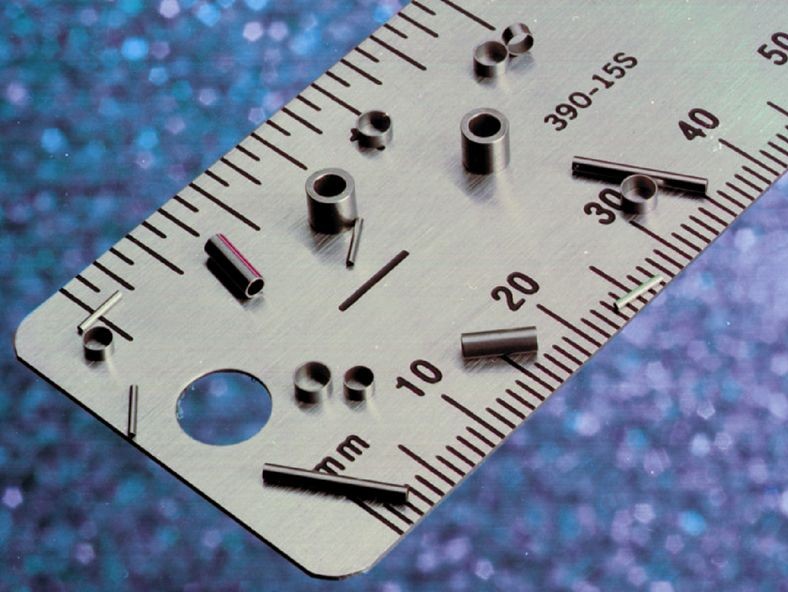

- Precision turned parts, such as shock absorber bolts, axle nuts, driveshafts, interface fittings, pneumatic tool accessories, shafts, machinery parts, flanges, nozzles, and housings, have outstanding surface finishes.

- Turned components can be used in a variety of industries, including electronics, automotive, appliance, HVAC, marine, medical, telecommunications, petroleum, and optical thanks to their extensive range of applications.

- Tight tolerances are used to manufacture complicated components that make up precision medical products. To ensure adherence to medical standards, they are made of sanitary-grade materials like titanium and stainless steel. Turned parts offer extraordinary precision, depth, and dimension thanks to novel turning methods that enable design capabilities and structural advantages that cannot be cost-effectively replicated with any other manufacturing technique.

- Industries employ turned components to secure goods in place. Precision components are advantageous to the aerospace, oil, and defense industries. Since they provide high levels of performance for their desired application, precision components are also used in the medical, electronics, and hydraulics industries.

Advantages of Precision Turned Parts

- CNC machining provides better performance. Components that have been CNC turned can run continuously before any maintenance is necessary. With fewer needed adjustments, there may be a significant amount of labor savings during the production process.

- CNC turned components operate in accordance with pre-programmed instructions that specify the precise paths and directions to be taken. Excess material can be drastically reduced, producing cheaper costs and creating enticing sale prices.

- Any production process might be dangerous if the employees are straying. Let's use the examples of laser cutting, punching, welding, or hearing raw materials. Every movement of CNC machines can be incredibly exact and versatile with pre-programmed instructions thereby highly reducing the likelihood of workplace accidents.

- Quality is one argument for picking a sector with a CNC machine shop to meet production demands. The use of machines makes sure that all fundamental procedures are optimized, boosting the output's uniformity and speed. It takes less time if the technician doesn't have to drill manually. Except for repairs, CNC equipment does not need to be turned off, assuring continuous output. Machines don't have to deal with breaks or fatigue, making production a more efficient process. Procedures that ordinarily require multiple pieces of equipment and numerous hands only require one.

Choosing the Right Precision Turned Part Manufacturer

To make sure you have the most beneficial outcome when purchasing precision-turned parts from a precision turned parts manufacturer, it is important to compare at least 5 companies using our list of precision-turned parts manufacturers. Each precision turned parts manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each precision-turned parts company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple precision-turned parts companies with the same quote.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

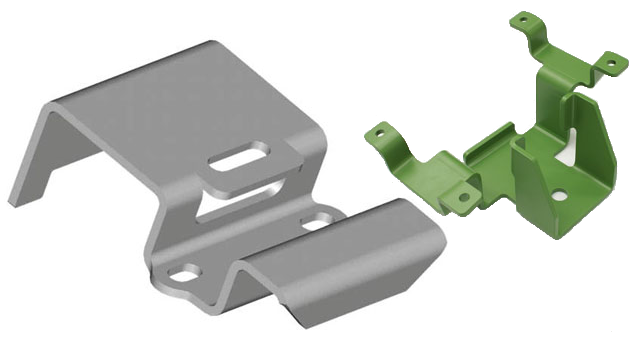

Metal Etching Metal Fabrication

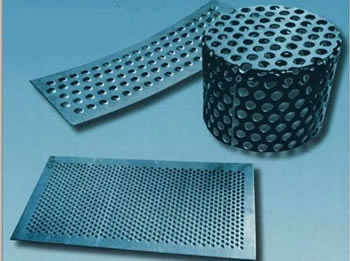

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

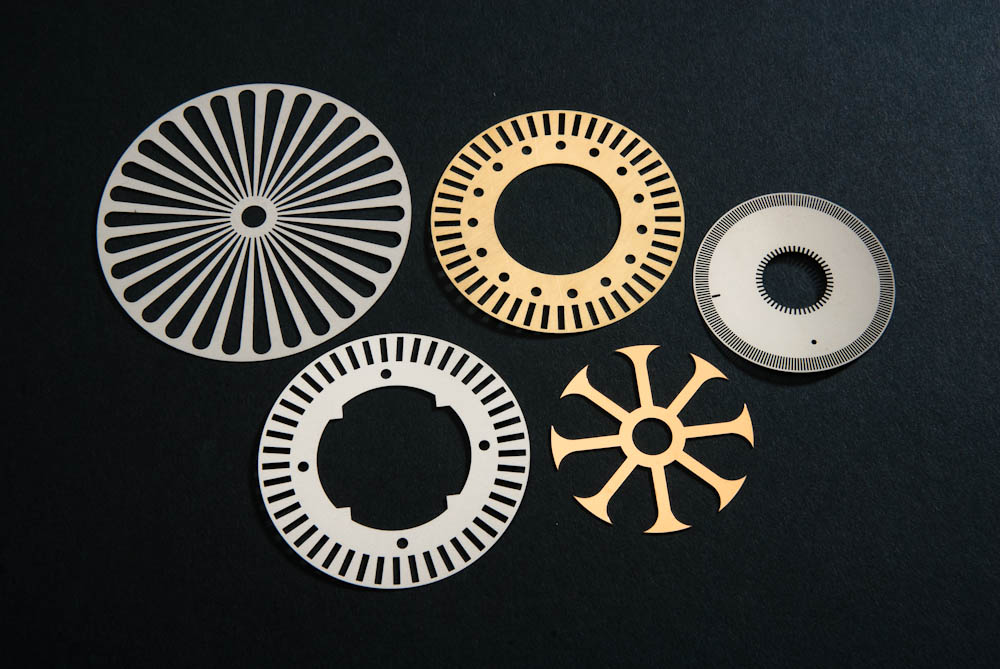

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services