Davison-Rite Products Company

Davison-Rite Products CompanyRequest A Quote

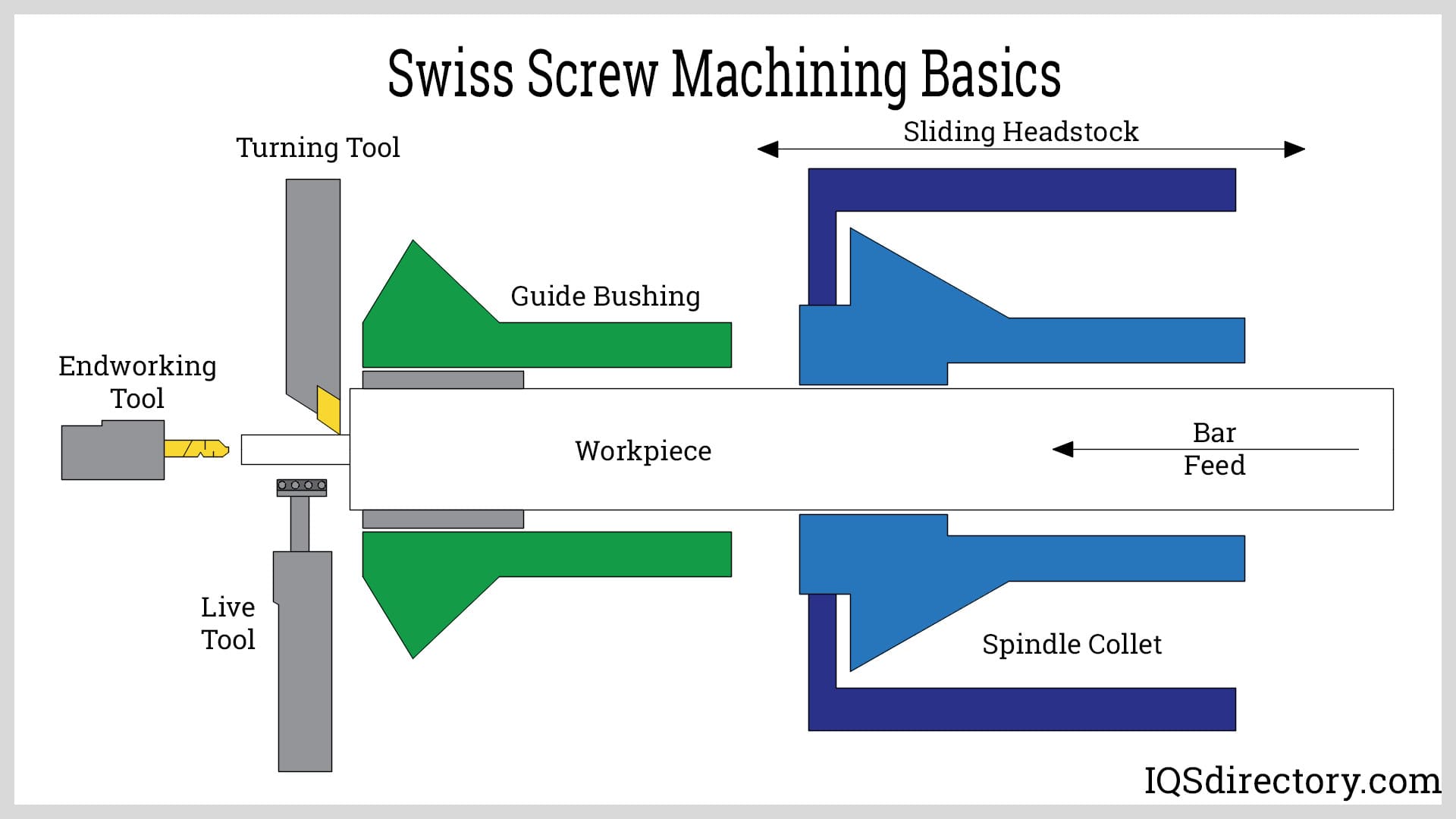

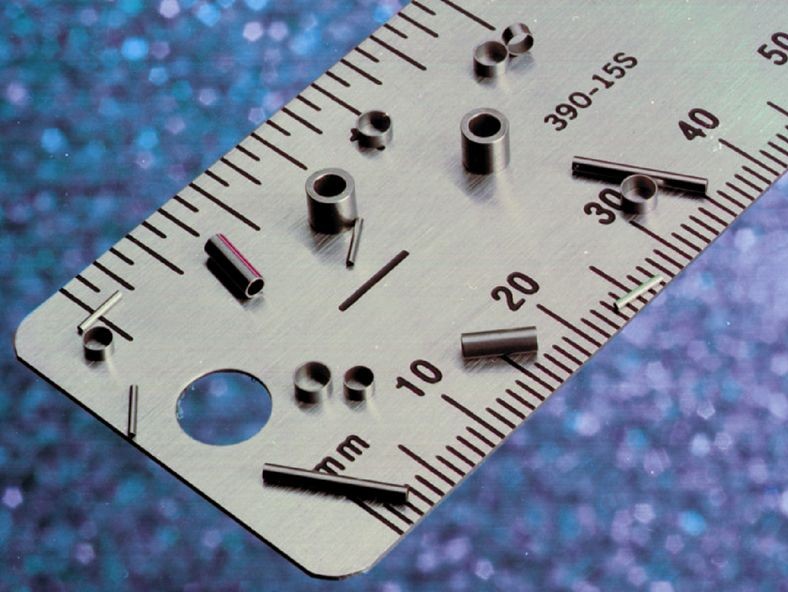

Livonia, MI | 734-513-0505Davison-Rite Products Company is a renowned manufacturing firm specializing in the production and distribution of high-quality Screw Machine Products. With a rich history spanning several decades, our company has established a strong reputation for delivering precision-engineered components to a diverse range of industries. At Davison-Rite, we understand the importance of precision and reliability in the manufacturing sector. That is why we have honed our expertise in screw machine technology, ensuring that our products meet the highest standards of quality and performance. Our state-of-the-art facility is equipped with advanced machinery and a team of skilled professionals dedicated to producing exceptional screw machine products. Screw Machine Products: Our comprehensive range of Screw Machine Products caters to various industries, including automotive, aerospace, electronics, medical devices, and more. We offer an extensive selection of components, such as bushings, shafts, pins, connectors, fasteners, and other custom-made parts. These products are manufactured with utmost precision and adhere to strict quality control measures to ensure dimensional accuracy and superior performance. Service Capabilities: 1. Custom Manufacturing: At Davison-Rite, we have a strong commitment to meeting our customers' unique requirements. Our experienced engineers and technicians work closely with clients to understand their specifications and design custom screw machine products accordingly. We utilize advanced CAD/CAM software and modern manufacturing techniques to bring our clients' visions to life. 2. Material Expertise: We have in-depth knowledge of various materials commonly used in screw machine products, including stainless steel, aluminum, brass, bronze, titanium, and various engineered plastics. This expertise allows us to recommend the most suitable materials for specific applications, considering factors such as strength, durability, corrosion resistance, and cost-effectiveness. 3. Quality Assurance: Quality is the cornerstone of our operations at Davison-Rite. We adhere to stringent quality control processes at every stage of manufacturing. Our facility is ISO 9001 certified, and we maintain strict compliance with industry standards. Through rigorous inspections and testing, we ensure that every screw machine product leaving our facility meets or exceeds customer expectations. 4. Just-In-Time Delivery: We understand the importance of timely delivery to our customers' production schedules. With our efficient production planning and streamlined logistics, we offer just-in-time delivery options to ensure that our clients receive their screw machine products exactly when and where they need them. 5. Research and Development: As a forward-thinking company, we invest in ongoing research and development efforts. Our dedicated R&D team stays up to date with the latest advancements in screw machine technology, materials, and manufacturing processes. This allows us to continually improve our products and stay at the forefront of the industry. Conclusion: Davison-Rite Products Company is a trusted provider of precision-engineered Screw Machine Products. With our commitment to quality, expertise in custom manufacturing, and focus on customer satisfaction, we have become a preferred partner for numerous industries. Whether you need standard components or customized solutions, we are dedicated to delivering superior products that meet your specific requirements. Partner with Davison-Rite Products Company for reliable screw machine products and exceptional service.

Broaching

Broaching CNC Machining

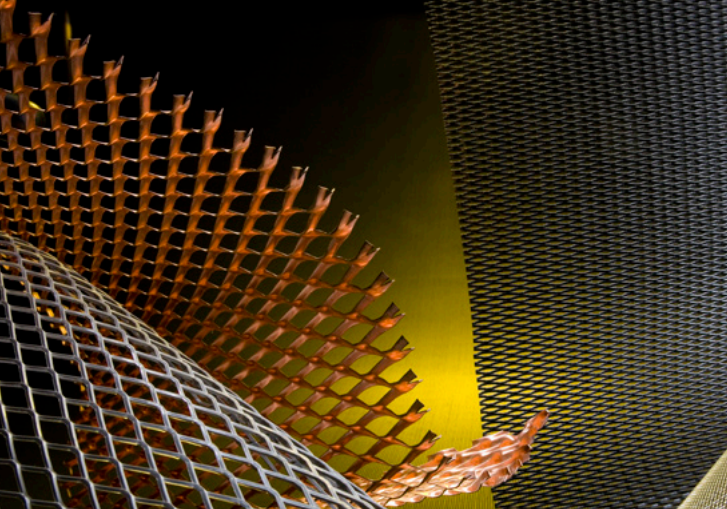

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

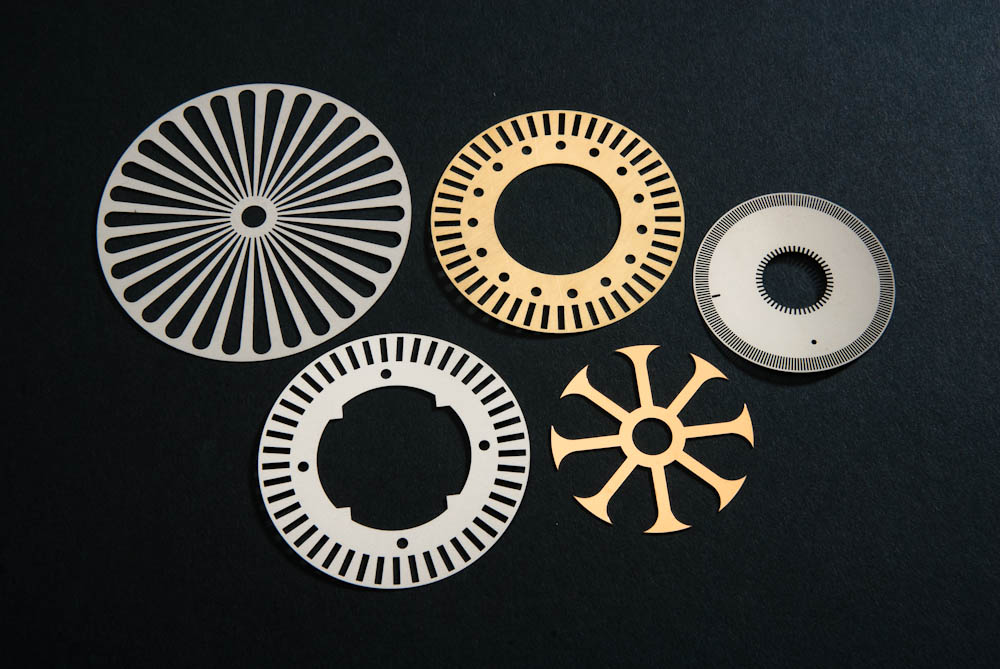

Laser Cutting Metal Etching

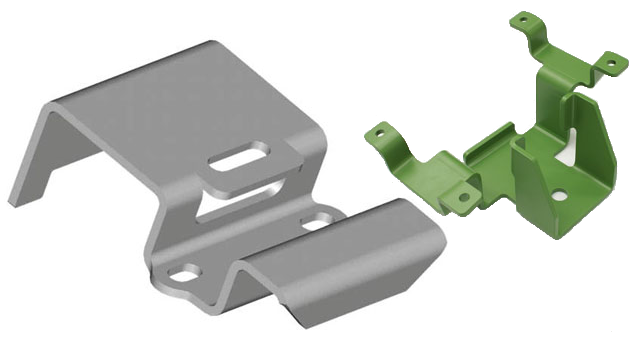

Metal Etching Metal Fabrication

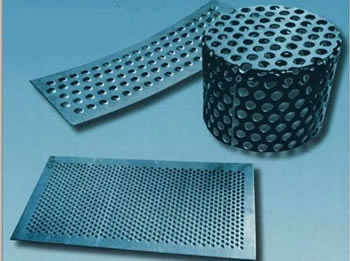

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

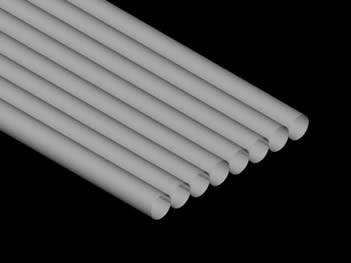

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

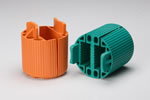

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services